Marine Power - CEO in Focus: Chris-Marine’s Jens Groth

Malmö, Sweden-based Chris-Marine is long-tenured in the business of keeping engines running smoothly, efficiently. Led by its energetic young CEO Jens Groth, this 60-year-old- company finds itself in transition: firmly rooted in its traditional business of creating the tools and technique to keep commercial ship engines running smoothly, but at the same time transitioning its revenue to include services, particularly as ships at sea increasingly run with fewer, less experienced crew. Add new mandates from IMO aimed at cutting ship emissions, and Chris-Marine today finds itself front and center in the EEXI requirements to limit CO2 emissions with limits on shaft power output, courtesy of its recently launched Shaft Power Limitation (ShaPoLi) solution.

“Chris-Marine is, and has always been, a manufacturer of tools for repair and service of big diesel engines,” said Groth, noting that the company is historically conservative by nature, which has enabled the company to thrive and grow for more than have a century, weathering the maritime industry’s notorious cyclical swings. “Our prime customers [are traditionally] shipping companies, but that has expanded into diesel-driven power plants as well. Competence around maintenance, repair, service of diesel engines, that is the basics of our products. That's where we come from the last 60 years. But in recent years, we're also moving more and more into the monitoring side, digitalization.”

Maintaining engines onboard ships is particularly topical as part of the automation and autonomy discussion, as the size of crews have been shrinking for years, and the technical competence onboard has weathered a similar degradation. Chris-Marine, in turn, has been challenged itself to deploy digital solutions across its tool sets, making them easier to use, getting quality results even when used by less-skilled hands. “We come from a product, 100% product run company, which was moving more and more into service with our tools,” said Groth. “This was [so we could be] super good at using our tools so we could improve them. But within the last five to seven years, we have moved more into consultancy, to partner with our customers because we have so much know-how about diesel engine maintenance and repairs. More and more shipowners have asked us to come and do the service instead of them buying the tool.”

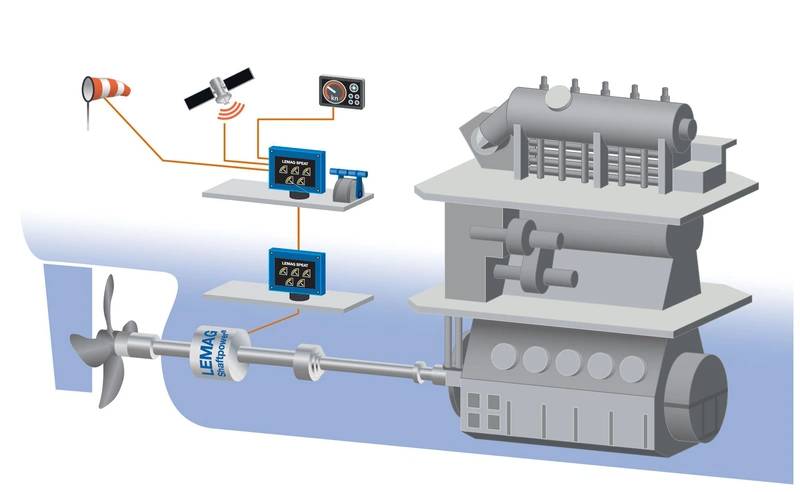

The Chris-Marine ShaPoLi Solution. Image courtesy Chris-Marine

The Chris-Marine ShaPoLi Solution. Image courtesy Chris-Marine

The Energy Transition

While there is a fixation on energy transition in the maritime sector, finding suitable alternative fuels to help dramatically reduce emissions from commercial ships and boats at sea, the path forward is neither straight nor short as every action has a reaction, which sometimes have results what can be dramatic and unexpected.

Groth and his Chris-Marine team aim to get in on the ground floor, and enjoy close relationships with several OEM engine designers to ensure that it is developing the tools needed to work on the power plants of tomorrow.

“One area we see changing is fuel technology, due to the fact that heavy fuel oil with high sulfur content is being reduced or removed, with alternative fuels coming up,” said Groth. “Every time you introduce a new fuel into the combustion chamber, you change the environment of the combustion area” which sometimes results in unintended consequences, remembering back to when the sulfur cap came into effect and several engine types had problems with their cylinder liners. “So we developed several products for monitoring the condition of the cylinder liners,” said Groth, which teamed well with its line-up of tools designed to restore the correct geometry and cylinder liner surface.

Changing the fuel also can have dramatic impact on the fuel injectors. “When you change fuel, obviously you change the fuel injectors and that means a lot of new technology is coming out of our Danish office. And this year we had a big technology development within exactly this area.”

So Chris-Marine is engaged from the beginning, understanding the new technical parameters of the engines and their components, creating the tools and technique to help make them operational again when something inevitably fails.

“If you maintain your engine well, you get the best running engine and the best running engine has the least emissions.” Jens Groth, CEO, Chris-Marine. Image courtesy Chris-Marine

“If you maintain your engine well, you get the best running engine and the best running engine has the least emissions.” Jens Groth, CEO, Chris-Marine. Image courtesy Chris-Marine

Enter ShaPoLi?Increasingly Chris-Marine has become a part of the decarbonization discuss, as the IMO has set the target to mitigate CO2 emissions from ships by at least 40% by 2030 compared to 2008 levels. To meet this target, IMO has adopted EEXI and CII, a set of amendments to existing regulations to reduce greenhouse gas emissions from vessels.

Chris-Marine developed a ShaPoLi, a solution that will enable existing ships to meet the minimal energy efficiency level to comply with the upcoming regulations.

“With the new [EEXI & CII] regulations coming into play, shipowners have to find a solution to comply,” said Groth. “There are basically two types of products that can assist: Engine Power Limitation (EPL) and ShaPoLi.”

In simple terms, EPL is analogous to putting a brick under your gas pedal, limiting the amount of throttle you can give on the highway, for example.

“ShaPoLi is more advanced,” said Groth, “We have a torque meter constantly monitoring the torque on the shaft, and on top of that, we have developed a control system that constantly monitors the torque. If you are going above the limit allowed within the EEXI framework, you'll get an alarm on the bridge. It can fully automatic, or you can have it where the crew can react and override it,” which could be needed in the case of saving life at sea, or securing the ship from piracy or severe weather. The keys to the ShaPoLi system are it provides better control of speed and power date, and there is no need to modify the machinery. The solution will help customers to comply with the EEXI regulations and also help them monitor and optimize their ship CII ratings in the future.

Image courtesy Chris-Marine

Image courtesy Chris-Marine

The Path Ahead

Keeping Chris-Marine and its global operations on its steady growth pattern is a continual challenge, particularly when it comes to attracting and retaining personnel. Groth said the challenge is significant as “we are a traditional company engaged in a conservative market. We are not Google or Ikea or Mercedes. We are Chris-Marine, and we are super proud of where we come from; but if you want to climb the career ladder super quick and you want to become a manager of 50 people within three years, this is not the place.”

But it can offer the allure of being a company with global operations, serving to keep one of the world’s key industrial sectors up and running.

At the helm of Chris-Marine since 2015, Groth has been on a mission to grow the business both organically and via acquisition. One of the key acquisitions happened just one year later, when in 2016 Chris-Marine acquired the monitoring products from German company LEMAG, now Chris-Marine Germany. Chris-Marine also opened a new company in the Florida, during the pandemic, as it has a strong customer base in the cruise lines. While the timing was unfortunate, the end result is a stronger Chris-Marine today, with a key new presence located in Pompano Beach, FL, in close proximity to a strong customer base.

Globally Chris-Marine has eight companies, with its headquarters in Sweden and a physical presence in China, Denmark, Ecuador, Germany, India, Singapore and the U.S.

[Before the pandemic] it was easier to convince a customer to pay for us flying from Copenhagen to Mozambique, or Siberia or Shanghai,” said Groth, which is a trend on the decline both from the monetary aspect but also the environmental implications. “It's more important [than ever] for us to be closer to our customers.”

Machining of engine frame sealing surface using Portable Lathe from Chris-Marine. Image courtesy Chris Marine

Machining of engine frame sealing surface using Portable Lathe from Chris-Marine. Image courtesy Chris Marine