Lube Oil: Less Can be More

Ever tightening environmental regulation in the maritime sector means that effective fuel and lube management onboard ships will become a defining issue for vessel owners; a bigger factor in profit versus loss. With new international and regional regulations come new technologies, and when a company the size of ExxonMobil talks, people tend to listen. We sat with Iain White, field marketing manager, ExxonMobil Marine Limited, in Germany earlier this fall to discuss the company’s largest product launch ever.

As regulation continues to evolve regarding fuel quality and emissions from commercial ships, so too must technology evolve on vessels to ensure that owner not only stay in compliance, but that they also stay in business. In response to the proliferation of ECAs in Europe and North America, ExxonMobil has this year introduced its new variable-sulfur cylinder oil – Mobilgard 560 VS – which is designed for use with residual fuels spanning both high and low sulfur levels. “The ECA legislation is the driver for change,” White said. “Customers have to change the fuel, they do not have an option, so that leads through to having to consider changing their lube oil to meet that fuel requirement.” While the product officially was available globally in October, it has been in use on the company’s U.S. Jones Act client’s ships since the summer of 2012, as quite simply the demand was there to meet new Emission Control Area (ECA) requirements in the U.S. “With North American coastal waters set to become the latest region to implement a 1.0 percent sulfur ECA in August 2012, Mobilgard 560 VS will provide ship owners and operators with the convenience of being able to use the same cylinder lubricant as they transition from deep-sea operation with traditional fuels to ECAs in coastal areas that demand the use of low-sulphur fuel,” White said.

According to White, the concept behind Mobilgard 560 VS is quite simple: it is an advanced lubricant which offers ultra low feed rate capability for slow speed engines while simultaneously enhancing operational performance and reducing engine wear. As is the signature of any of the oil majors, ExxonMobil approached the problem scientifically confirmed by lab and field tests, and the result is the meeting the requirements of leading engine makers, including MAN Diesel & Turbo, Wärtsilä and Mitsubishi Heavy Industries. “With crew quality being a challenge for our customers now, they want a simple solution. So a single cylinder oil that meets the requirements of all of the different sulfur levels, we feel, is the way to go,” White said. “We will be replacing the two cylinder oils we have today with the new one.”

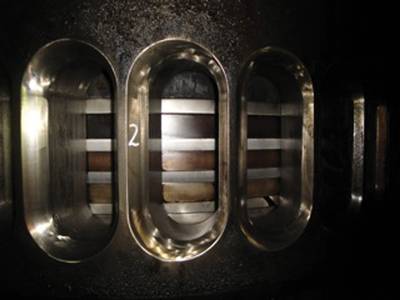

According to the company, across a wide range of field trials that were conducted using fuel with variable sulfur levels of between less than 1% to nearly 4%, Mobilgard 560 VS, a 60 BN oil, consistently delivered piston cleanliness, a result achieved even while operating at the same low feed rates as Mobilgard 570, a popular, high-performance 70 BN cylinder oil. Furthermore, in vessels operating under extreme conditions, such as slow steaming or ultra-low feed rates down to 0.45 g/kWh, tests showed how Mobilgard 560 VS can help minimize scuffing and wear.

Less is More

As ExxonMobil has stepped up its involvement with shipowners in the monitoring and management of lube oil, White said the company has found some interesting information regarding the real-world use of lube oil, findings that could help all shipowners save money.

“What we’ve discovered – that is kind of a game changer – is that most of our customers use too much cylinder oil,” White said. “Your typical chief engineer is conservative and wants to ensure his vessel works effectively and safely. He wants to sleep at night knowing that everything is going to stay running, and he thinks that a little more cylinder oil is a little extra insurance policy.” We have seen everything from them using the manufacturer’s recommendation up to 100% too much, he said.

Chief engineer sleeping habits notwithstanding, the practice is wasting money, and with escalating oil prices and tighter margins it is not a luxury that most can afford. Along with new Mobilgard 560 VS and its range of Mobil-branded marine lubricants, ExxonMobil also offers valuable support services that can help ship engineers optimise feed rates, extend cylinder and ring life, and minimize oil consumption.

For example, its MobilGard Cylinder Condition Monitoring Program – which at the moment has more than 400 ships in the program, according to White – is designed to help ship engineers detect any potential changes in cylinder condition, such as elevated iron levels.

In various field trials, the use of Mobilgard 560 VS, in conjunction with the MobilGard Cylinder Condition Monitoring Program, enabled several companies to operate with cylinder oil feed rates of nearly 25 percent below original equipment manufacturer (OEM) recommended levels, with extremely low wear rates.

“I think with market conditions as they are – things are really tough out there for shipowners – I don’t know that we’re at the bottom of the cycle, but we’re certainly low in the cycle, owners have to operate more cost effectively,” White said. “The typical chief engineer that has had this mind set for years: is he going to change? Well, there’s a huge cost driver to change.”

www.mobilgard.com

(As published in the November 2012 edition of Maritime Reporter - www.marinelink.com)