Jan De Nul's Next-Gen Offshore Wind Installation Vessel Launched in China

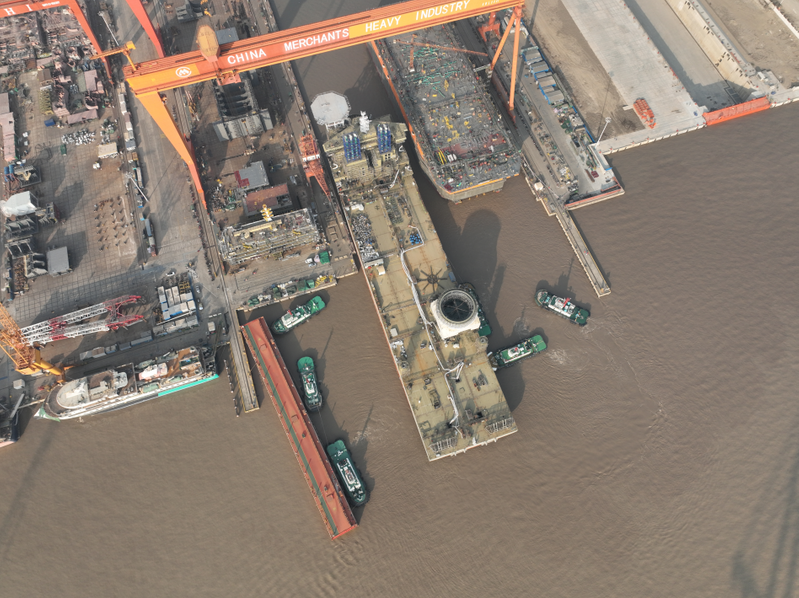

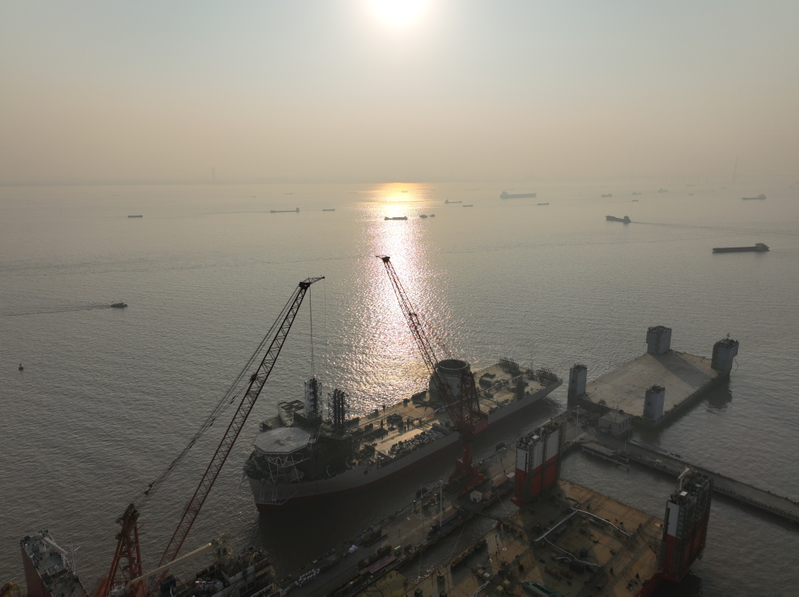

Offshore installation firm Jan De Nul said Thursday that Les Alizés, its next-gen floating offshore installation vessel had been launched at the CMHI Haimen shipyard in China.

The vessel is now ready for the final construction phase, including sea trials, to be completed by H2 2022.

Les Alizés will be the largest Heavy Lift Vessel in Jan De Nul’s fleet, able to install XXL offshore wind components, in floating conditions and with ultra-low emissions.

The launch started on January 2, by flooding the dry dock in which Les Alizés was built. Once afloat, Les Alizés was moored alongside the adjacent quay wall.

On Wednesday, the official launching ceremony took place at the CMHI Haimen shipyard, in the presence of the shipyard management and Jan De Nul Group representatives.

"The final phase of the vessel’s construction can now begin, including sea trials. Les Alizés is due for delivery in H2 2022 in good time for her first assignment in Germany for the construction of Gode Wind 3 and Borkum Riffgrund 3 Offshore Wind Farms, transporting and installing 107 monopile foundations for the offshore wind major Ørsted," Jan De Nul said. Credit: Jan De Nul

Credit: Jan De Nul

Philippe Hutse, Director Offshore Division at Jan De Nul Group: “The construction of our offshore floating installation vessel Les Alizés is well on track. We can look forward to delivery later this year, so that we can continue to build the future of offshore renewable energy. Together with our Offshore Jack-Up Installation Vessel Voltaire, which is also under construction in China, we will have the perfect set of offshore installation vessels that will be able to install current and future generations of offshore wind farms."

Les Alizés will be equipped with a crane having a lifting capacity of 5,000 tons. Credit: Jan De Nul

Credit: Jan De Nul

Low emissions

According to Jan De Nui, to reduce the vessel’s CO2 emissions, the power plant onboard is a hybrid setup. The arrangement combines diesel-driven generators with battery and drive technology to optimize engine loading and to recover the potential energy returned from the heavy-lift crane. To further reduce the carbon footprint of installation activities, the ultra-low emission vessel can run on second-generation biodiesel that reduces the fuel carbon footprint by up to 90%.

As an ultra-low emission vessel, Les Alizés is equipped with a highly advanced dual exhaust filter system, removing up to 99% of nanoparticles from emissions using a diesel particulate filter (DPF) and reducing the NOx emissions and other pollutants by means of a selective catalytic reduction system (SCR) to levels in accordance with EU Stage V regulation. Les Alizés and Voltaire will be the first two seaworthy installation vessels in the world with extremely low emissions, Jan De Nul said.

Les Alizés will mainly be used for the construction of offshore wind farms, but will also be suitable for decommissioning offshore oil and gas platforms. Credit: Jan De Nul

Credit: Jan De Nul