Is Stern Tube Damage Declining?

It might be easy to blame EALs, but the ongoing causes of stern tube damage are varied, and possibly declining.

Environmentally Acceptable lubricants (EALs) gained market traction with the introduction of US VGP regulations in 2013. Since then, DNV has observed two major trends.

- The first, starting in 2013 was early life damage, either during sea trials or within the first five years of operation, where aft stern tube bearings typically failed under extreme load conditions.

- Then from around 2018, vessels of about 10 years of age and above started experiencing bearing damage, with many of them having lubricant contamination problems. The affected vessels were often delivered with mineral oil then converted to EALs and subsequently suffered sealing problems.

DNV rules support the use of mineral lubricants, EALs and water lubrication and are complemented by relevant technical publications with recommendations to overcome known issues. In its November 2023 guidance, DNV recommended installing a proactive warning system that alerts the crew to any concerning rate-of-rise in bearing temperature or if the draft of the vessel could leave the propeller partially immersed. In addition, on older vessels DNV recommends that EAL viscosity should be increased one grade up from the design specifications of the installation.

“Our recommendations are simple. Please have good control over your oil quality in the primary barrier, the aft sealing system,” says DNV Senior Principal Engineer Arun Sethumadhavan.

“Our recommendations are simple. Please have good control over your oil quality in the primary barrier, the aft sealing system,” says DNV Senior Principal Engineer Arun Sethumadhavan.

Photo Courtesy DNV

“Our recommendations are simple. Please have good control over your oil quality in the primary barrier, the aft sealing system,” says DNV Senior Principal Engineer Arun Sethumadhavan. “The solutions are not intrusive.”

Current sentiment seems to bear that out. Manufacturer Panolin noted strong support for EALs at a 2023 trade show. “As the shipping industry looks toward the future, sustainability is becoming a priority. In fact, it was the overriding theme at Sea Asia.”

However, insurer Gard remains concerned about EAL failure, and company analysts voiced them in October 2023 when they released an analysis of the last 10 years of claims. One of the things they noted was the IACS suggested limit of 1% water being allowable: “The speed of hydrolysis depends on various factors, for example, chemistry of the oil, temperature and additives. The most important factor, however, is the quantity of sea water present in the lubricant. The 1% limit is quite ‘relaxed’ for EALs.” Alignment checks during stern tube repair procedures courtesy of Marine and Industrial Transmissions.

Alignment checks during stern tube repair procedures courtesy of Marine and Industrial Transmissions.

Photo courtesy Marine and Industrial Transmissions

Still, the Gard data shows claims in excess of $5,000 increasing in number up to 2020 and then declining: from 134 in 2020, to 118 in 2021 and 87 in 2022 – a noteworthy decline.

Ship repairs are the day-to-day concern of UK-based Marine and Industrial Transmissions, and the company’s engineers don’t see any current trends in the causes of stern tube damage. A recent case study demonstrates what can go wrong though: upon interviewing the Chief Engineer of a vessel they were recently called out to, it was discovered that the stern bearings had overheated due to loss of lubricating fluid. This caused the bearing faces to become seized to the shaft momentarily, leading to accelerated bearing wear, with the bearing material migrating through the lubrication system. Rudder, propeller and shaft needed to be removed in dry dock before the required repairs could be completed.

“Design fault” was a common category assigned to Gard claims, which could indicate shipyard errors unrelated to lubricant choice.

DNV Head of section for Propulsion and Steering in Oslo, Øystein Åsheim Alnes explains one of the key challenges. Different operating conditions mean different loading conditions on different parts of the aft stern tube bearing. “The weight of the propeller in combination with hydrodynamic propeller loads in certain operating conditions can lead to aft end edge loading. The most critical parameter for ensuring that doesn’t happen is to slope the bearings to better match the slope of the shaft. A good bearing design is important.” DNV’s November 2023 guidance suggested the use of double-sloped aft bearings to optimize load distribution.

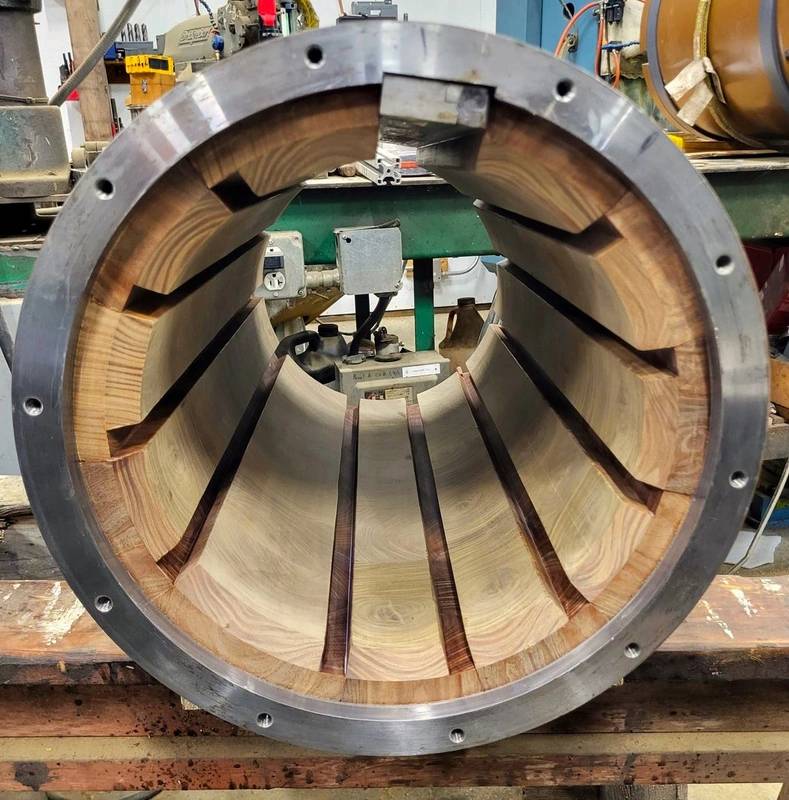

A large number of the incidents analyzed by Gard were attributed to ghost fishing gear that enter the stern tube seal area causing seawater to contaminate the lubrication oil. A 2022 study by CSIRO scientists estimated that the amount of longline fishing gear littering the ocean each year can circle the Earth more than 18 times. Additionally, 14 billion longline hooks litter the sea each year, but this too could be a declining problem. Huge as they are, the researchers found lower levels of fishing gear losses in this study than in a previous study published in 2019 – potentially the result of better weather forecasts and improved marking and tracking of fishing gear. Lignum Vitae is engaged in engineering tests in collaboration with Hydro Tech in Canada. (Image courtesy of Lignum Vitae)

Lignum Vitae is engaged in engineering tests in collaboration with Hydro Tech in Canada. (Image courtesy of Lignum Vitae)

President Bob Shortridge says Lignum Vitae's water-lubricated stern tube bearings stand out for its longevity and shock resistance. The company places a strong emphasis on addressing the issue of high bearing wear, particularly in slow sailing vessels. In pursuit of optimal performance, Lignum Vitae is engaged in engineering tests in collaboration with Hydro Tech in Canada. These tests are focused on modeling bearing performance under different loads and speeds, enabling customization of clearance and pitch angles. This approach deviates from the one-size-fits-all method commonly observed with other bearings and has led to dramatically reduced bearing replacement time in drydock.

Unsurprisingly, seawater-lubricated bearings pioneer Thordon Bearings welcomed the publication of Gard’s data. “Let’s not forget any oil leak, big or small, can be catastrophic to the marine environment and marine life, with some EALs found to be only slightly less damaging than the phased-out traditional oils,” said Thordon Bearings VP of Business Development, Craig Carter.

Water lubrication has faced its own challenges over the past decade. Individual class societies have gradually updated their rules to reflect the modernization of seawater lubricated bearing materials and systems. Previously, seawater-based systems had to comply with costly five-yearly shaft withdrawal requirements. They are now subject to the same extended 15 to 18-year shaft withdrawal inspection periods as those using oil lubrication, subject to monitoring criteria.

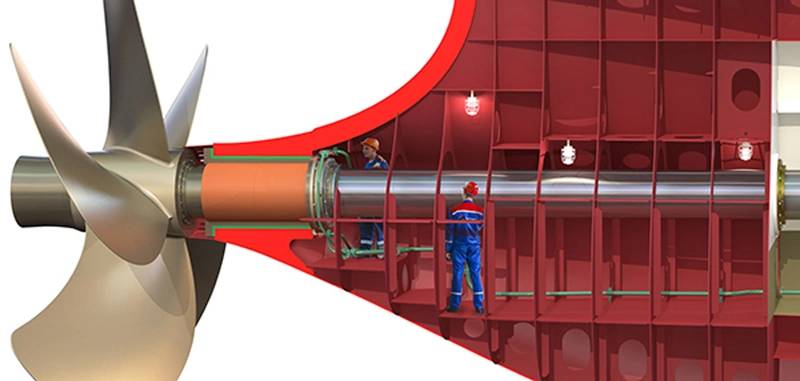

Thordon announced in December 2023 that it is forming the Blue Ocean Alliance with Wärtsilä to promote a stern tube-less ship concept. The design replaces a vessel’s stern tube with an irregular shaped chamber that allows a shorter, water-lubricated propeller shaft to be inspected and maintained while the vessel is afloat.

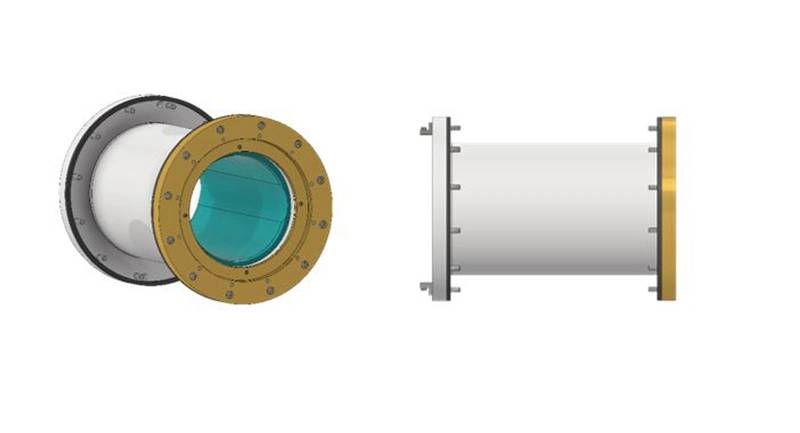

Wärtsilä has also introduced EvoTube, a simplified system with fewer components than a conventional stern tube system, which is suitable for both oil and water lubrication systems. The inboard seal is mounted directly on the aft bearing housing, and the forward bearing is replaced with a standalone bearing inside the engine room. Its design optimizes space utilization and eases maintenance tasks.

So, the coming decade promises to be interesting and hopefully less concerning than the last for the Gard analysts.

A stern tube-less ship concept courtesy of Thordon Bearings.

A stern tube-less ship concept courtesy of Thordon Bearings.