Interview: Rolf Stiefel, Winterthur G&D

The May 2019 edition of Maritime Reporter & Engineering News features a 10-page feature section on "Thought Leadership" in the marine power sector. Here we extract and present the interview with Rolf Stiefel, Vice President Sales, Winterthur Gas & Diesel Ltd., in its entirety.

Please put in perspective and discuss – using your career as the time span – the current environment and pressure to reduce emissions in the maritime industry.

When I started in the marine industry (coming from the power generation markets) back in the early 2000’s, the main focus was to achieve higher outputs at affordable CAPEX. Fuel consumption slowly gained importance with increasing energy prices over the years, which became even more important after the 2008 financial crisis. Emissions where not as relevant, they were just required to be IMO com-pliant.

Today we are facing a totally different situation. Besides the rules and regulations around NOx, SOx, we are now also very aware of CO2, GHG, Black Carbon and particulates, well ahead of the regulations! The awareness of this industry on our impact on the environment has dramatically grown. It is great to be a part of this shift.

How does this pressure compare to the other industries you serve? What technologies or ‘lessons learned’ from other industries are you applying to maritime solutions? Please be specific.

In the power generator industry, where I was working prior to my time in the marine industry, we had already introduced the lean burn Otto cycle Wärtsilä four-stroke engines back in the late 90`s. There, through regulation like TA-Luft and so on, the limitations especially on NOx and SOx where already in place and were more stringent than the IMO rules we have now for 2020 onwards. The introduction of the LNG burning engines to the marine market was, from that perspective, absolutely no surprise. Basically, we are applying technologies which have existed for quite a long time to a new market. And of course, the engines have been marinized and made fit for application on board of a ship.

While I’m certain that your organization’s investment in Research & Development is broad and continuous, can you point to one or two areas where you are investing most heavily, explaining why?

The major area of our investments is in three new engine testing facilities in Winterthur and in China. Focus of the development is to further increase engine efficiency and to further reduce the emissions of our X Series Diesel engines and our X-DF Series LNG burning engines. These testing platforms will also be used to research alternative future fuels like Hydrogen, Ammonia, Methanol and Bio fuels. Another focus area is around the digitalization of our engines and preparing them to be able to operate in “unmanned ships” of the future. These are the significant areas of development not only for WinGD but for our industry as a whole.

FUEL: There is (justifiably) vibrant discussion surrounding fuel choice. From your discussions with your clients, do you see one fuel emerging today as the ‘next big thing?’

The next big thing on fuels is LNG. We are a long way from identifying a fuel which offers the same viability, in terms of infrastructure, beyond LNG at the moment. LNG is the necessary bridge which is getting us closer to a carbon neutral future. Already today about 30% of all new engines ordered to propel deep sea vessels are using LNG as fuel. The reasons are compelling: lower emissions, less CO2 and offered at a very attractive price compared to 0.5% sulfur fuels. As an entire industry, we need significant collaboration in order to bring the next future fuel to the same level of availability. The uptake of alternate fuels such as hydrogen and ammonia in short-distance routes are exciting, progress is happening. But the viability as a fuel for ocean-going vessels is just not there yet. That’s why LNG is the right choice now.

Autonomous Operations: Put in perspective ‘Autonomous Marine Operations’. What is your definition, and is it a real conversation with your clients today, or a topic far in the future?

The WiDE (WinGD Digital Expert) system we offer to our clients is highly appreciated. It improves the way operational data on a day to day basis is analysed to improve operations and predict maintenance. Nevertheless, such a system is still far away of enabling an “autonomous shipping” if this should mean a vessel “without a crew”. For the moment for the deep sea shipping this advancement looks to be still far away. Supporting crews to be better able to deal with the complex systems on board and to improve operational excellence is our primary target.

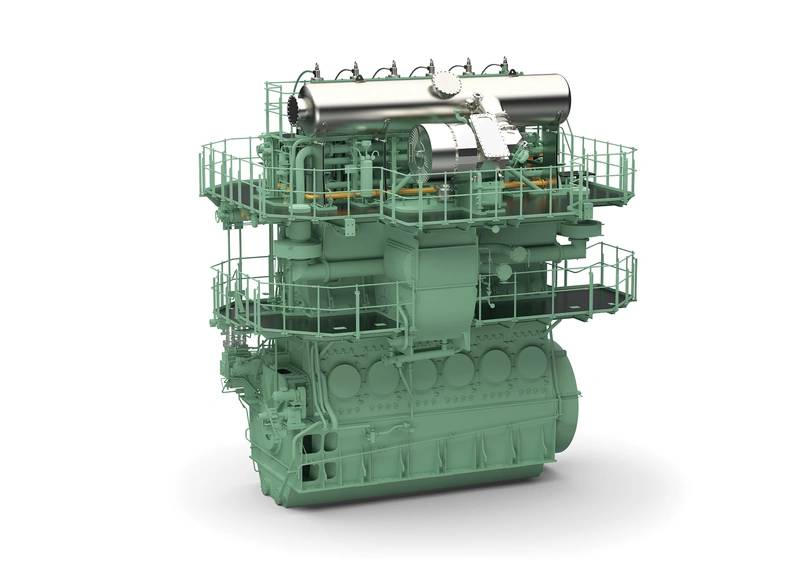

The CMACGM 9x 22,000 TEU container vessels ordered in CSSC group with WinGD 12X92DF engines. They will feature the biggest ever Otto cycle engine with over 60,000 kW of power. Image: WinGD

The CMACGM 9x 22,000 TEU container vessels ordered in CSSC group with WinGD 12X92DF engines. They will feature the biggest ever Otto cycle engine with over 60,000 kW of power. Image: WinGD

How is your organization preparing for the advent of Autonomy in the maritime space?

We are researching the digitization of the propulsion engines to prepare for more autonomy. One of the great ways that our industry is changing is in the growth of collaborations, bringing expertise together to offer the best future solutions. We are working closely with many partners for advancing in this area.

From an Engineering, Design & Manufacturing perspective, what do you count as the biggest challenge today to produce innovative, next-generation propulsion plants that meet or beat emission regulation?

For the next decade or so the case is clear: There is still so much capacity to grow LNG as fuel across our industry. We are really just at the beginning with LNG so there is room for further improvement of efficiency and emissions. Further developing our X-DF engine series is a high priority.

Going beyond 2030 there needs to be a strong potential “non fossil” fuel which can be applied for deep sea shipping in order to reach the IMO 2050 GHG targets. The biggest challenge for us here is to know which fuel will be the one to be chosen. This does not only depend on what we (as engine designers) consider to be the best choice but what will be “left over” for shipping considering the needs of Power markets, road transportation, air traffic, etc. all facing the same challenges. We can’t all compete for the same clean fuel – there needs to be an increased capacity across the board. It is a highly political issue which needs a strong “market consent”. Whatever the fuel will be, our job is to be able to convert it into propulsion power for ships at highest efficiency and with low emission with two-stroke engines. Considering our history as engine designers, I am confident in our ability to do so.

The IMO last year dropped the gauntlet to reduce maritime emissions 50% by 2050. Is that target achievable, and if so, which fuels or technologies will be key to success?

The target is achievable yes. It will need broad collaboration in the industry looking at the entire ship and the full logistic chain. To some extent, non- fossil fuels will be needed in this equation.

Same Question as above, but comment on the prospects of ZERO CARBON emissions?

Quite a challenge and raising the bar. I believe a “carbon neutral” future is more realistic for shipping. That in and of itself will be a great achievement.

Please discuss a recent product (or service) introduction(s) that you see as truly transformational for owner/operators of commercial ships and boats.

The introduction of the WinGD X-DF low pressure gas engine has been truly transformational for shipping. Launched in November 2013 we have secured more than 200 engine orders to date and have achieved almost 100% of the market share when two-stroke DF engines are selected. We understand the pressures faced by today’s shipping industry and simple solutions are key. Our X-DF engines offer ship owners a proven, reliable way to improve their environmental footprint while at the same time, increase efficiency while maintaining simple, and safe operations.

Please provide a recent case study or two – a finished vessel or a recently announced project – that best illustrates some of the innovative marine power solu-tions your company provides.

The CMACGM 9x 22,000 TEU container vessels ordered in CSSC group with WinGD 12X92DF engines. They will feature the biggest ever Otto cycle engine with over 60,000 kW of power.

The 80 plus orders placed for LNG carriers all featuring WinGD X-DF engines in different configurations. The X-DF propulsion system is now the standard for LNG carriers built worldwide today.

Our ability to burn an NG-VOC (Natural Gas - Volatile Organic Compounds) fuel mix on our WinGD X-DF engines. Successfully tested a year ago on our test engine in Trieste, Italy, this technology will be operational in 2020 on two 125 000 dwt shuttle tankers for AET. This capability has considerable implications for both the oil and gas industry, and the environment. VOCs are a waste product from crude oil handling and transport which represent both a hazard and a loss of revenue to oil and gas producers and shippers. Historically, they were either discharged into the atmosphere or burned off. Now, with the development of our X-DF engine’s new fueling mode, VOC can be turned into a viable source of energy.

BIOGRAPHY:

Rolf Stiefel, Vice President Sales, Winterthur Gas & Diesel Ltd.

Rolf Stiefel was born in 1965 in Germany. He has a master’s in industrial engineering from Hamburg technical University. After graduation and some years in the process Industry, he joined Wärtsilä as General Manager of Power Plant business unit in Germany in 1997. Since 2001, Rolf has been working in various positions as Director of Sales in the Ship Power business unit in Wärtsilä Europe and Asia. After leading the global sales and application team, of the 2-stroke business of Wärtsilä he moved 2015 into the independent two-stroke engine business renamed WinGD (Winterthur Gas & Diesel Ltd.) As Vice President Sales.

Rolf has extensive knowledge and experience in efficient and environmentally sustainable propulsion systems for merchant ships and is a strong advocate for a cleaner and more sustainable shipping industry through the use of LNG as marine fuel.