Interview: Juha Kytölä, Director of R&D and Engineering, Wärtsilä

As maritime faces transcendent changes in terms of decarbonization and automation, Juha Kytölä, Director of R&D and Engineering, Wärtsilä, discusses how this Finnish maritime technology powerhouse is investing in the technologies and facilities that will drive the maritime industry for the coming generation, including insights on its unique arrangement for a future fuel engine testbed onboard Wasaline’s MS Aurora Botnia.

- To start off, can you give a scope of the Wärtsilä R&D investment?

We invest heavily in research and development, about 4.1% of our annual turnover. So last year $255 million was used for research and development activities; not only for engines activity, but the major part of that does go into the engine R&D.

- This is a transcendent time in the maritime industry. How do you see it?

The transition taking place in the industry is huge [offering many] challenges, [and also offering many] opportunities. My 34-year career has always been closely linked to technology development, and I have been involved in introducing new fuels [to market]. We put a lot of focus on introducing liquefied natural gas as a fuel for shipping, which was a very big step [and has made] a big contribution toward decarbonization.

Today ship owners have the will to optimize their operations, not only for economical drivers, but especially for the environment. These are fantastic times for people in research and development; it’s motivating for our people, working to contribute to decarbonization in a global business.

- Wärtsilä has a relatively new sustainable technology hub in Vaasa, Finland. Can you tell us about the new facility; specifically, what does it add to Wartsila’s overall capability in helping to create and deliver decarbonization technologies in the maritime sector?

We indeed have made great investment within Wärtsilä for developing the facilities and the infrastructure so that we can make steps forward in developing new products and solutions. Here in Finland, in Vaasa, we have a long industrial heritage with more than 100 years operations on the same site, which consists of older and modern facilities. Wärtsilä made a bold decision a few years ago to completely build new facilities, to relocate the activity about two kilometers from the older place, close to the harbor of Vaasa City. It’s a $272 million investment which brings us about 60,000 sq. m. space under one roof, serving our research, development, testing and validation, as well as the production for producing our engine products to the markets, both of the marine market but also on the land-based energy markets. It’s a fantastic facility, inaugurated in mid-2022, with a lot of modern facilities.

- Can you discuss the challenges in manufacturing and customer support while you’re planning for the future, a future that still has many questions, while supporting the legacy technology and those that rely on it?

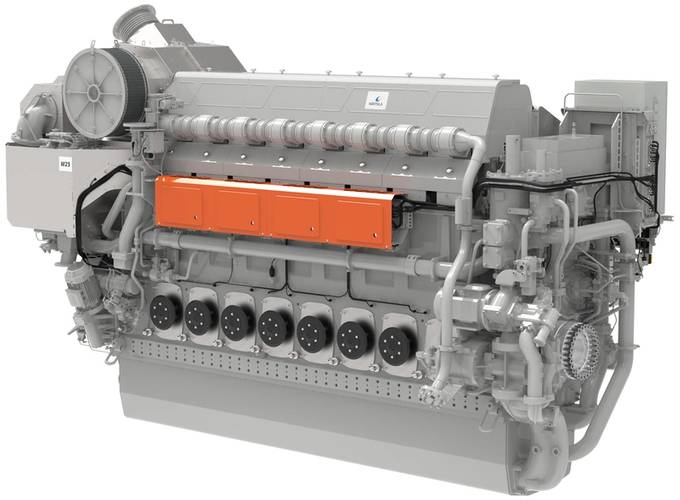

Climate regulation is pushing for continuous improvement, fuel efficiency, and also the fuels that are being used. Today the marine industry is using around 300 million tons of fossil fuel per year, and there is a great need now to replace that with solutions which are not causing climate impact. One of those fuels we are developing to be used for marine is methanol. Methanol is a good fuel. It can be produced from bio sources or also from synthetic basis. So using hydrogen and capturing CO2 or carbon. Today there is production of methanol already in the world. If we count in the global production, that’s around 90 million tons per year, but that is used by other industries, too. So at the same time we develop the technologies for using methanol, we need to find ways to ramp up the production volumes for these alternative fuels, where methanol is one candidate. Image courtesy Wärtsilä

Image courtesy Wärtsilä

- There are still so many unsettled questions on the fuel and technology transition we’re undergoing now, so it might seem a bit premature but ‘what’s next?’

It’s a great question about the longer-term future, what’s coming and where’s our focus. When we started [the path toward] decarbonization, we had our eyes on the year 2050 [premised on rules from the International Maritime Organization]. Now our programs – short-, medium- and long-term – are all developed to support achieving that [2050] goal.

The first step is looking at the process to make the transition possible; it’s not an overnight change, it’s not black and white.

We start from energy efficiency, lowering the fuel consumption of vessels, which not only helps the environment but it’s helping the economics case [for shipping] too.

LNG is a very good transition fuel from well to wake, with 5 to 20% [efficiency] improvements.

The next steps are fuels which are carbon neutral, fuels like methanol on biosynthetic basis. Eventually [we’ll move to] fuels that don’t have any carbon in the fuel itself. A lot of focus is put now already to support the long-term development of fuels like ammonia and hydrogen, too. So, there are many steps in the transition, which are ongoing, with all focus on supporting the industry to take the pollution down to zero by 2050.

- Can you put in perspective how AI with all of its promise and peril will impact the work that you do within the walls of Wärtsilä research and development center?

Artificial intelligence and machine learning are indeed, in some segments, a powerful way to further improve operations. The engines being produced today for ships have very powerful automation and control functionality built-in, computers and sensors monitoring the operation continuously.

And we are also controlling functions. These engines typically have from six to 20 cylinders in one engine, and already now combustion is being controlled in every single cylinder separately, every single combustion separately.

Already now, machine learning and artificial intelligence is applied into these technologies to have the feedback loop. They’re controlled as efficiently as possible for learning how the product is operating in that environment. Artificial intelligence is also used for controlling operation of installed engines and systems onboard of ships. With remote monitoring it’s possible to get the signals from ships to operational centers, where we are able to use artificial intelligence to monitor the signals, to learn the real condition, helping to discern what is normal, what is abnormal. In our current system it takes two weeks for the AI to learn an installation, a ship, and thereafter it can give guidance on what would be beneficial for the ship to modify. It also gives hints on how to further make savings on fuel or operating costs, even learning about how to further extend the service intervals. So artificial intelligence is already a big part of activities.

- Can you point to one recent project, either internally at Wärtsilä or externally on one of your client’s ships that most clearly illustrates Wärtsilä’s decarbonization aspirations in maritime?

Yes, this collaboration is best evidenced with the collaboration we have in this vessel from Wasaline, Aurora Botnia, where we collaborate on new technologies. [We have an engine on the ship] which is running on natural gas, and we have developed and validated onboard on a ship a technology which is cutting the methane emissions from such an engine by about half. So it’s taking the cleanest engine in the world, and make it even better. Thanks to the collaboration and the operation onboard a vessel, we could validate and prove the concept.

Watch the full interview on Maritime Reporter TV: