Interview: Joe Hudspeth, BAE Systems

Joe Hudspeth is the Director of Business Development for Global Marine at BAE Systems in Endicott, N.Y. BAE Systems offers complete, efficient propulsion and auxiliary power systems utilizing electric technology. Hudspeth has been involved with maritime sales, marketing and product development since 2000. He currently serves as a regional co-chairman for the Passenger Vessel Association, is a judge for the Worldwide Ferry Safety Association student design competition, and frequently speaks and writes on maritime and ferry related issues. Hudspeth lives in Bellingham, Wash. and he holds a Bachelor of Arts in Business Administration from Western Washington University. Here he discusses the pace and progress of BAE Systems’ HybriGen technology.

Please walk us through the BAE Systems’ experience with electrification.

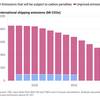

BAE Systems has been aware of the need to address emissions for decades, and this challenge has become one of our valued missions and is the purpose behind our Power and Propulsion Solutions Division located in New York. It’s here in America that we proudly build our core technology, the HybriGen system, which has grown out of 20 plus years of investment and innovation. We first demonstrated our success in HybriGen electric power and propulsion systems in the transit bus industry. We’ve been able to leverage over 20 plus years and 13,000 systems in operation today to bring that over to the maritime sector. During the last five years, we’ve worked with a variety of boat builders and operators and naval architects to help get people toward zero emissions, and that’s really what BAE Systems is about, is getting people closer and closer to zero emissions.

We believe that mitigating emissions through electric systems has a compounding effect, and that not only eases the burden on our precious environment, but it helps people to experience lower noise in their vessel, reduce crew fatigue through less vibration and financially helps the bottom line through reduced fuel expenses and maintenance costs. These are all reasons why it makes sense for people to consider hybrid and electric technology in this path toward getting to zero emissions. One other thing is sometimes it’s the small things that get overlooked, but they’re really a nice benefit and should be considered into the ROI analysis. For example, an electric ferry, they don’t have to go to the fuel dock anymore; and we all know that going to the fuel dock takes time and you have to wait to bunker and it’s expensive. But now with an electric ferry, every time you pull into the dock and plug in, you’re essentially taking on fuel. That’s really an added benefit to help people consider taking on that new technology.

(Image: BAE Systems)

(Image: BAE Systems)

Where has the technology found success in the marine industry to date?

We have found that hybrid and electric propulsion technology makes a lot of sense for applications such as research and survey vessels. Vessels like Norwalk Aquarium, Spirit of the Sound and City University of New York’s research vessel, they’ve been able to promote environmental stewardship while operating on sensitive coastal areas, and they do that with our hybrid and electric technology.

Additionally, tour operators, such as Red & White Fleet in San Francisco, they’ve been able to conduct quiet and low emissions tours and really ease their carbon footprint in an urban landscape setting, all at the same time they’re experiencing and reporting fuel savings of around 30%, which is very significant.

Then if you look at our transportation sector, hybrid and electric technology works there too, and we’ve seen it demonstrated in Washington’s Kitsap Transit passenger ferry, the Waterman that’s providing daily commuter service, all with clean improving hybrid technology, and the Harbor Harvest vessel has become a first in America to demonstrate hybrid technology in the field of short sea shipping. They’re able to do crossings across Long Island Sound and bringing refrigerated cargo as well as passengers in a very clean and environmentally friendly way.

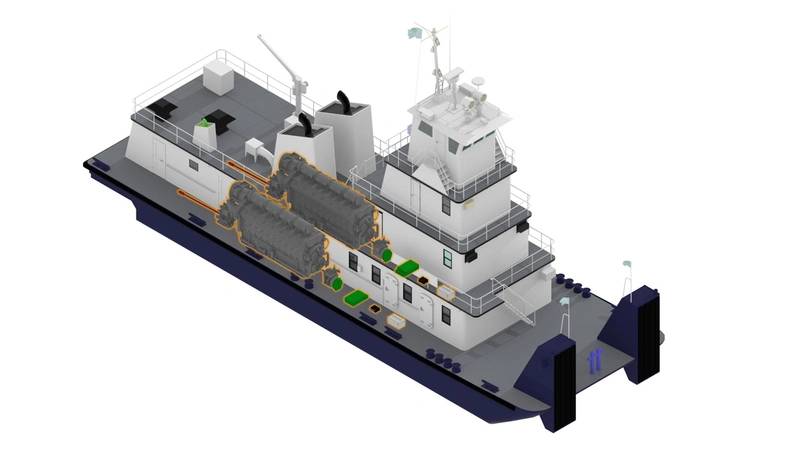

The list goes on and on, but I’ll leave you with one more application and that’s in the inland towboat market. Well, they need extra horsepower that may not make sense for a hybrid or electric propulsion system. We can use a system to generate power off of the main engines and utilize batteries that essentially eliminates the need for a generator. If you can pull the generator out of the equation for those boats, it saves fuel and maintenance costs, and really adds to the bottom line.

So, hybrid is happening. The electric power and propulsion in America is really buzzing, and it’s going along cleanly and quietly.

(Photo: All American Marine)

(Photo: All American Marine)

As you discussed, your portfolio is wide and diverse. And no two projects are exactly the same. So, can you discuss how the HybriGen system supports the very needs and requirements of the marine industry? And is there any change in your approach of your system offerings?

We certainly realize that our customers need flexible solutions, and we realize that all craft are different from pilot boats to patrol boats, eco-tour vessels, to high-speed ferries. Each one has different routes, different operational characteristics and performance requirements. Along the way, looking at these applications, we realize that some operators and applications are closer to zero emissions than others. That’s where BAE Systems has been able to step in and provide systems that are designed to get people to zero, no matter where they are today. It’s a journey and it’s a path, and we have solutions that can meet each application no matter where they’re at.

We found that the best approach is to develop partnerships, not only with naval architects, but with the operators themselves and with shipyards. We do that right from the start in the initial design phase, all the way through construction and sea trials and getting the certification from the regulatory agency or U.S. Coast Guard. So, if we do that, we can create lasting legacies in the systems that we are supplying.

Just to walk you through this a bit, we first start by identifying the vessel’s power needs for both the propulsion power and the hotel loans. Once we have a solid understanding of that data, we can essentially map down to the minute how much energy the vessel will consume when it’s in operation. We use this information to drive the system design, and for BAE Systems, our system is really modular and it gives us flexibility in our offering.

We understand that there can be challenges—for both builders and some operators—to adapt hybrid or electric technology, or even fuel cell technology as it’s newer for our industry. But it’s not new for BAE Systems; it’s not new technology overall. So, we’re able to leverage our experience, understanding and knowhow in this partnership to get through U.S. Coast Guard certification or approval by the regulatory agency.

So how do we do that? Well, at the core, more of our HybriGen power and propulsion system is really an off-the-shelf technology. It’s a proven technology built here in America, and each application is going to be different, and that’s where the HybriGen flexibility comes into play. We have the capability to go above and beyond when needed, and we can add engineered and tailored solutions if that’s a requirement. But our approach is to deliver a package solution that provides all of the propulsion power and the auxiliary hotel load power. We can give our customers the assurance that our system is proven because they can look here in the maritime industry at these vessels that are currently in operation.

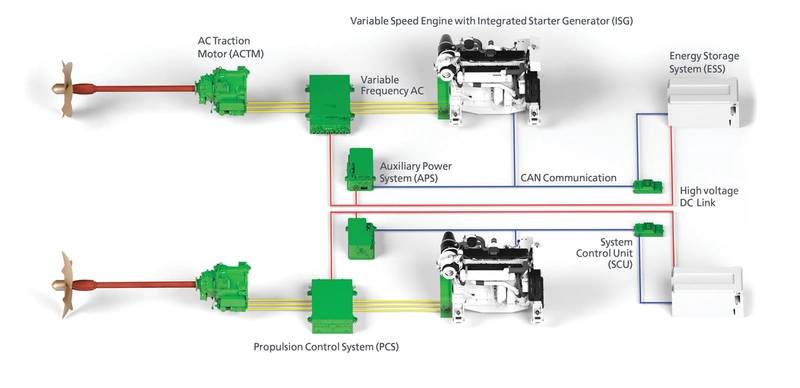

We offer three basic configurations for this HybriGen system, and the first system is our HybriGen power and propulsion system. That system provides electric power for all of the accessory loads, as well as the propulsion system, but it does so by using the power of lithium ion batteries and the supporting power of an efficiently driven variable speed diesel generator. This system takes diesel-electric technology and really gives it a twist. First and foremost, the system is engineered to utilize silent and electric power from the batteries as much as possible. Again, it’s not just the propulsion power, but it’s also the hotel load power too. When additional power is needed, that is when the variable speed genset will come into play.

What I love about the variable speed genset is that it only turns on when it’s needed, and it only operates at a level of power that is being required and demanded for the application. It eliminates the need for the generator to operate at higher power levels. This cuts down on fuel consumption and reduces the emissions. If you think of it this way, most people have a fixed speed genset on board their vessel, and it’s operating very inefficiently most of the time. Say you have a 100-kilowatt genset, but you only need 20 kilowatts of power. Well, that genset is sitting there churning away, producing a lot of extra power that just cannot be absorbed and used. Our approach is to operate that engine just at the power level that is required, and we eliminate a lot of harmful emissions, and that the problem of slobbering, or wet stacking, that just goes away with a variable speed genset. That’s what I like about it, and that’s part of the HybriGen standard system.

While this system works for many applications, there are still some applications out there that might need the additional horsepower of a conventional diesel mechanical propulsion system. We get that, and we’re not trying to reinvent the wheel for all applications, but we feel like we can take conventional propulsion and twist it, and do it in a better way.

That’s where HybriGen assist system comes into play. It’s a parallel hybrid system that can augment the power of a conventional diesel propulsion system. We do that with the additional power of an electric motor that can feed into the propulsion system through a power take in and provide additional boosting power. This is beneficial for applications that require higher horsepower that might stem up into the Tier-4 power range. We can provide that power without having to generate the need for any aftertreatment systems. We do that all electrically.

But conversely, on the flip side, we can operate the electric motors and provide all electric slow speed propulsion for a vessel. This is very beneficial if you think of a ferry that’s pushing against the dock while loading passengers or a harbor tug that is loitering and station keeping all day. Those vessels are currently forced to operate their propulsion engines at a minimum idle speed that may be excessive, and in doing so, they’re burning a lot more fuel than what they may need. Our HybriGen system could do that all electrically, quietly and emissions free.

Lastly, I just want to mention that we can provide a power-based system, and our HybriGen power system is a simple configuration that generates power for the hotel loads by harnessing that power off of the main engine. If we do that income combination with an energy storage system, we can reduce the need for gensets, eliminate extra maintenance, extra fuel burn, and we’re saving costs for the bottom line.

(Image: BAE Systems)

(Image: BAE Systems)

I think you might agree that, generally speaking, the marine industry can be somewhat conservative when it comes to the uptake of new technology. So, if I’m a vessel owner and I’m considering an all-electric or a hybrid-electric solution, what are some of the things that I should be concerned about or asking about?

We realize that there are some customers and operators out there that might have some hesitation about going electric or embracing hybrid technology. That’s why BAE Systems is really trying to develop solutions that can meet customers where they’re at today. There certainly are a few factors that need to be considered when going electric or even hybrid. It starts with defining the power needs, evaluating the suitable technology solutions that are out there and conducting a consideration of the shore site infrastructure and how much energy storage the vessel can physically accommodate. We’re able to help with all of that. In order for this to work, the solution has to be a win-win.

We work to get the customers to see a complete picture of what they have and what could be. I want to underline that while this technology is new to the industry, to our industry, again, it’s not new technology overall. The technology is safe and it is proven. Our regulators, the coast guard and classification societies, they have guidelines in place that further enhances the safety and proper installation and operation of these systems.

We also realize that it’s important for the crew to be trained on the components of the system. We put forth a lot of effort into making sure that they’re familiar and comfortable with that technology. We want it to be effortless in the operation of the vessel. It’s a fully automated system, so the captain of a conventional vessel should be able to easily step behind the helm of a hybrid or electric vessel. It should look and feel that the same way in terms of the controls and the operation and control of the vessel movement. One piece of feedback that we got from some of our customers is that the vibration and noise of a conventional vessel provides a level of comfort at the helm. The captain is able to hear and realize that everything is working appropriately, and that essentially goes away when you have a quiet and low vibration electric propulsion system. So, we realized that we needed to provide clear visual indicators at the helm, and we’ve done that. There are some nuances, but these are things that can be overcome.

I also wanted to share that for operators who want to go electric today but may not have adequate shore-side infrastructure in place, that’s all right. By working with a modular system, we can grow the system over time and how our customers go down that path to get to zero emissions. It’s easy to add more energy storage, more batteries over time, along the way, and the system will adapt to that and realize that there’s more energy storage in place.

If you don’t have the shore site infrastructure, that’s all right too. The hybrid system uses self-charging technology, so it really can get operators to feel comfortable about investing in the technology and growing it over time. Same, we realized that batteries and energy storage is going to be continuously improving, and as that technology improves, you can bring it on board and our system will adapt to that as well, whether it be more efficient with the lithium ion batteries or a fuel-cell-based storage system.

(Image: BAE Systems)

(Image: BAE Systems)

This technology just doesn’t pop up, and developing it requires continual investment. When you look at your portfolio now and what it’s going to look like in the coming years, what’s new? What’s next?

We’re always looking to the future. Something new that we’re bringing to our HybriGen systems is geofencing technology, which we have successfully implemented in our transit bus industry, and now we’re bringing that over to maritime as well. It allows us to set up intelligent geofencing GPS based zones, and they use utilize the GPS technology to control the vessel and turn the diesel engines completely off, allowing the vessel to operate in zero emissions, quiet, all-electric propulsion when the vessel enters a user defined zero emissions zone. We feel that by offering this solution to current and future customers will help operators in sensitive coastal areas or passing through emissions corridors where they need to regulate how much emissions they’re producing.

I’d also like to talk about a couple of projects that are going to be hitting the waters soon. One of the projects that we’re most excited about is the SW/TCH e-ferry, and that will be the first hydrogen fuel cell powered hybrid electric ferry in America. That ferry is being completed right now, and utilizes BAE Systems’ electric motors and power management system and interfaces with the hydrogen fuel cells. While it is still consuming a fuel—a clean fuel, hydrogen—it is doing so in a very efficient manner, and it’s leveraging electric propulsion.

Secondly, we’re happy to announce that the University of Vermont is utilizing our HybriGen system and their new research vessel. This is a vessel designed by Chartwell Marine, and it is currently under construction at Derecktor Shipyards. Again, the research and survey vessel community has realized that implementing this hybrid propulsion technology is great for environmental stewardship.