CAT Debuts C175-16 in Germany

On the occasion of SMM 2012, Caterpillar Marine launched new diesel, dual fuel and gas engines.

The C175-16 from Caterpillar is the first Cat engine with core ACERT Technology, designed and built from the ground up, according to Robert Hallengren, Marine Products Director, Caterpillar Marine Power Systems. It offers maximum performance along with EPA Marine Tier 3 and IMO Tier II emissions compliance with no after treatment, and is positioned to comply with EPA Tier 4 and IMO Tier III rules. Introduced in Germany at the SMM exhibition, the engine already has more than two years field experience in other industries, including mining trucks and stationary power, and is moving now into marine and offshore oil and gas applications. It is available today in the 2001 to 2168 bkW power range; and will be available starting in early 2013 in the 2239 to 2550 bkW range. With unrestricted continuous and heavy-duty ratings, you get more power with plenty of room for growth, so you maximize productivity while minimizing cost of ownership.

The C175-16 is simply one plank in the Cat platform to broadly expand its strategic focus on maritime assets and their power needs, according to Nigel Parkinson, Managing Director, Caterpillar Marine Power Systems. “We are investing twice as much in R&D as we were 3 years ago, to help fill some of the product gaps,” he said.

The C175-16 is positioned as a fully integrated marine power sy stem, and boasts 13% more power for increased productivity, and a standard warranty on all factory packaged components to help drive down the overall cost of ownership.

C175-16

Marine Propulsion Ratings

Rating Speed (rpm) Power (bkW)

A 1600 2001

A 1600 2082

B 1600 2168

A 1800 2239

A 1800 2428

B 1800 2550

Engine Dimensions

Length, overall 4515 mm (177.8 in)

Width, overall 1857 mm (73.1 in)

Height, overall 2478 mm (97.6 in)

Weight (approx.) 13 041 kg (28,750 lb)

Bore 175 mm (6.9 in)

Stroke 220 mm (8.6 in)

Displacement 84.67 L (5166.88 cu. in.)

Rated Speed 1600 to 1800 rpm

Aspiration Turbocharged-Aftercooled

Cooling Jacket Water & SCAC

Refill Capacity

Lube Oil System 907 L (240 gal)

Cooling System 303.5 L (80.2 gal)

Fuel System Common Rail

Oil Change Interval 1000 hrs

Rotation (from flywheel end) Counterclockwise

Flywheel and flywheel housing SAE No. 00

Flywheel Teeth 183

Engine Management System A4 ECU

Configuration V-16, 4-Stroke-Cycle-Diesel

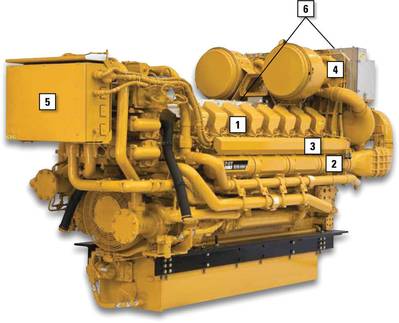

C175-16 Design Features

1 Caterpillar Common Rail Fuel System This system features electronically controlled, fully flexible injectors, enabling optimal combustion and low emissions at all levels, along with better transient response.

2 Cross-flow head design Improved airflow helps the air/exhaust flow meet emissions and optimize fuel consumption.

3 Simplified electrical system Allows for easy installation and maintenance, reducing up front and service costs.

4 New generation of turbochargers designed specifically for the C175

• Cast titanium impeller offers five times longer low-cycle fatigue life, and compressor blades are twice as resistant to high-cycle fatigue.

• Turbochargers are mounted on cast pedestals and center-positioned to eliminate external oil drain lines, reduce the chance of oil leaks, and improve turbo efficiency. The flexible bellows connections used on inlets/outlets of the turbine and compressor housings minimize leakage and provide isolation from

external vibrations, motions, and thermal expansion.

5 Marine Classification Society approved monitoring, alarm, and protection system: Offered as a factory-installed and warranted option; single source for the whole package.

6 Thermo-laminated heat shields for exhaust components Easier to install and remove, they save time and money during service. The no-gap fitting enhances safety with better hot spot coverage.

(As published in the October 2012 edition of Maritime Reporter - www.marinelink.com)