GEA Westfalia Separator BallastMaster ultraV USCG Certified

The BallastMaster ultraV developed by GEA Westfalia Separator for ballast water treatment has been awarded the "Alternate Management System" (AMS) certificate. The approval was awarded by the United States Coast Guard (USCG) on November 11, 2013. AMS is considered the standard for selection of suppliers for ballast water processing installations. The certificate is considered by the USCG to be a transitional measure until the type approval process has been formally implemented in American legislation. It follows the 2011 type approval of this unit in accordance with IMO.

In 2012 the United States implemented its own regulations for the treatment of ballast water via the USCG "Vessel General Permit" (VGP). These regulations are applicable for all new vessels whose keels were laid down after December 1, 2013. Existing vessels with keels laid down before then and ballast water capacities of 1,500-5,000 m³ must comply with the US regulations after their first scheduled docking in 2014. For existing vessels with a ballast water capacity of less than 1,500 m³ or more than 5,000 m³, this is applicable after the first docking in 2016.

Precleaning by mechanical filtration

BallastMaster ultraV is an extremely efficient mechanical and physical system solution for treating ballast water, including ballast water with high concentrations of organisms and sediment particles. The two-stage system works with mechanical pre-filtration and subsequent disinfection of the ballast water by means of UVC radiation without using and/or generating chemicals.

In the first stage, an upstream mechanical filtration system removes all organisms and sedimentary particles larger than 20 microns. This prevents sedimentary deposits from accumulating in ballast water tanks, and optimizes results in the second disinfection stage. Filter modules are cleaned automatically by vacuum extraction (self-cleaning).

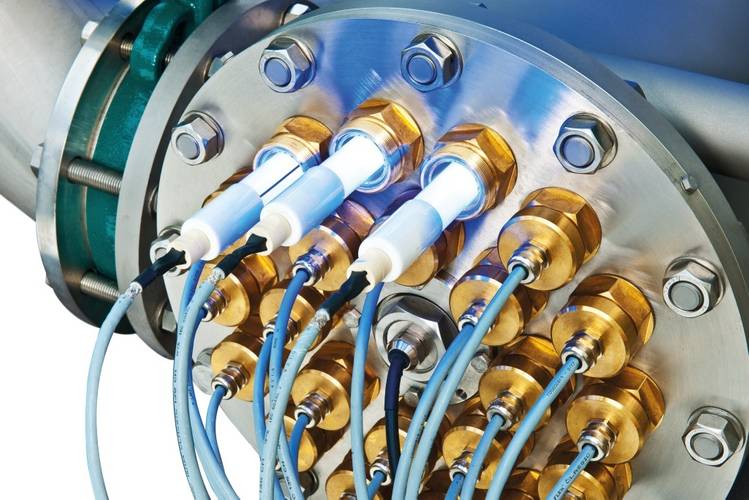

Disinfection by means of UV-C radiation

In the second stage, the prefiltered ballast water is disinfected by monochromatic UV-C radiation (254 nm), effectively destroying organisms such as bacteria or phytoplankton. Ultrasonic cleaning of the UV-C tubes removes biofilms and inorganic deposits efficiently and permanently.

us.westfalia-separator.com/applications/marine.html