Flawed Propeller Blade Caused Containership to Lose of Propulsion -NTSB

A containership transiting the Pacific Ocean lost hydraulic oil and propulsion after its propeller blade cracked, according to a report from the National Transportation Safety Board (NTSB). A blade on the vessel’s controllable pitch propeller system did not meet manufacturer design specifications, the investigation found.

The Matson containership Maunalei was travelling to Portland, Ore., from Anchorage, Alaska on August 11, 2022, for drydock repairs when the crew intentionally shut down the main engine due to problems in the controllable pitch propeller system, resulting in a loss of propulsion about 245 miles from the entrance to the Columbia River near Portland. The vessel’s controllable pitch propeller system may have lost up to 1,632 gallons of hydraulic oil. Damage to the vessel was estimated at $3 million.

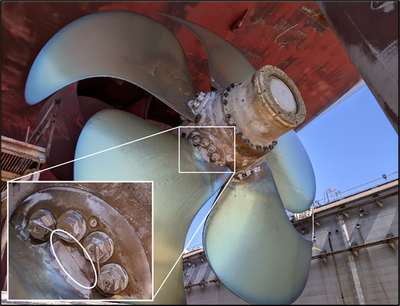

Upon drydocking, a third-party company found the cracks and fractures at the base of the no. 4 blade of the five-bladed propeller, where the blade was bolted to the propeller’s hub. The cracks initiated at the blade’s bolt hole counterbore radius and were consistent with progressive cracking due to high cycle fatigue. The company found the no. 4 blade did not meet manufacturer design specifications for engineering, material and chemical composition. The bolt hole counterbore radius was 0.2 millimeters smaller than the required 0.8 millimeters. It did not meet materials specifications for impact toughness, tensile and yield strength or percent elongation, and the silicon content exceeded the specified minimum.

Investigators found the crack and fracture that developed on the no. 4 blade was likely an isolated occurrence, as the blade did not meet specifications and a manufacturer’s analysis of other five-bladed controllable pitch propeller systems on similar vessels did not identify any other instances of cracks.

Following the loss of propulsion, the blade manufacturer revised the internal radius requirement—enlarging it—for all seven-bolt hole counterbores to improve fatigue fracture resistance.