Damen Dredging Equipment has unveiled its new electrically-driven E-DOP pump, every bit as capable as its hydraulic predecessor first introduced to the dredging industry 25 years ago. The new, electrical DOP pump offers added versatility to be more applicable to even more projects.

Damen Product Director Dredging, Olivier Marcus, said, “When Damen developed the DOP pump, over a quarter of a century ago, we did so with much collaboration from dredging contractors. As a result of their input, the DOP has gone on to become hugely successful in sand mining, operating in confined spaces and on small-scale work. This electrical version also answers calls from within the industry.”

The new system draws on recent advances in electric motor technology. According to the manufacturer, t`he E-DOP provides dredging operators the flexibility to carry out projects where clean and quiet operations are required. Possible applications include hydroelectric dams, where the power is already present, residential areas where low noise levels are vital or environmentally sensitive areas where the use of oils is not allowed.

Damen Dredging Equipment Project Manager, Erwin Muller, explained, “We have delivered electric pumps in the past. While they have been very clean – an advantage for projects with environmental concerns to address – they have also been large, heavy and expensive and have involved replacing the entire pump. Both electric motors and frequency converters are now smaller and cheaper, so, while we have had the E-DOP in development for some time now, we have been waiting for this technology to catch up with us. This advancing technology of permanent magnet motors combined with our standardization of components have minimized costs and optimizes the design.”

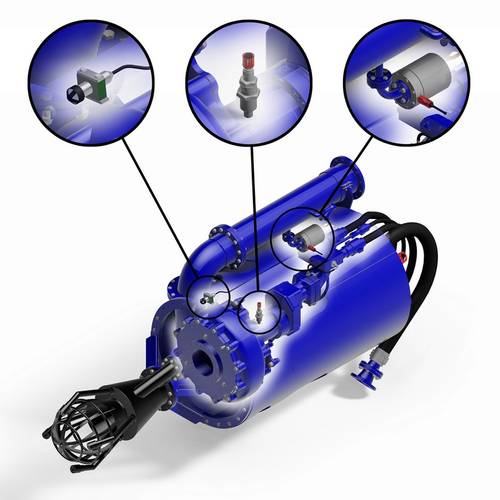

The E-DOP boasts a 93 percent drive efficiency, Damen said. Due to swift connection to power connectors, operators can install the system in their projects as a ‘plug and play’ configuration. Using wireless control connections, the whole system can be remote-controlled from a distance. The newly-introduced E-DOP pump can be powered by a generator set, resulting in quiet operations.

Easy maintenance is also a big advantage, points out Damen Design and Proposal Engineer Mark van ’t Veld: “There are no wear-causing fluids. And electric motors have fewer moving parts. So, an electric motor maintains its efficiency for longer. And the fact that we are able to replace the hydraulic motor with an electric one means that a client can choose whether to use a hydraulic or an electric version of the DOP pump on a project-by-project basis. “In this way, existing clients will also be able to take advantage of this new technology.”