DX for Ship Design: Aiming to Reduce Construction Time, Costs

Nippon Yusen Kabushiki Kaisha (NYK) and its group company MTI Co., Ltd. (MTI), in collaboration with Smert Design Co. Ltd., launched a trial to use 3D models in the initial design phase of ship construction. Ultimately, the aim of the project is to help optimize and shorten the ship design and construction process.

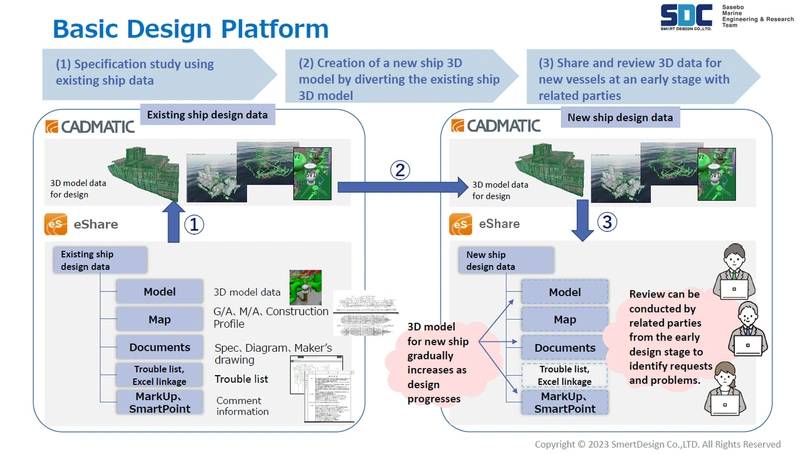

As part of the joint research project "Ship Design Streamlining Project by Front Loading," the three companies will implement the "Basic Design Platform" (BDP) into the ship design software CADMATIC and use it to design an LPG tanker for Kyoei Tanker Co., Ltd. to be built by Murakami Hide Shipbuilding Co., Ltd.

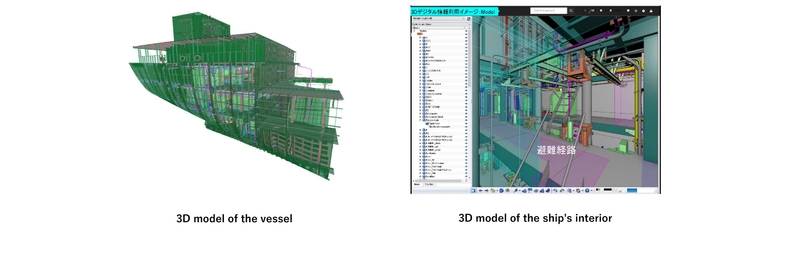

This trial aims to model 3D design information of existing similar and sister vessels and facilitate smooth decision-making by both shipyards and shipping companies for the exchange of requests, ideas, comments, etc., on the same system for the design applicable to this ship.

By visualizing the completed ship at an early design stage, the ship design can be understood intuitively. In addition, use of the same system by all parties involved reduces the work and processes required for design. This enables earlier decision-making regarding ship design, which has become more complex recently.

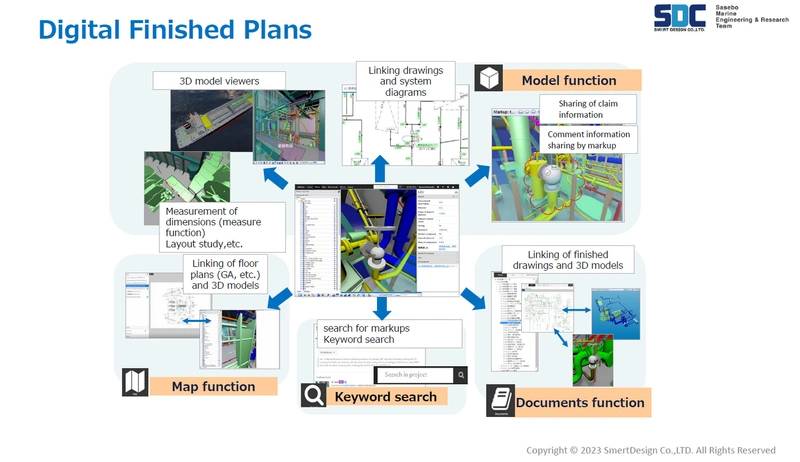

By using the 3D design as a 3D model-based ship management tool called "Digital Finished Plans" and by converting the finished plans, which were conventionally delivered as 2D drawings after completion of the ship, into 3D, the expectation is to reduce the workload on crew members in understanding the drawings.

Concept of Digital Finished Plans. Image courtesy NYK

Concept of Digital Finished Plans. Image courtesy NYK