DSME Returns for More Dual-Fuel Engines

Four two-stroke ME-GI engines ordered for two LNGCs.

MAN Diesel & Turbo has received an order for four MAN B&W 5G70ME-GI engines in connection with Daewoo Shipbuilding & Marine Engineering Co.,Ltd. (DSME) agreeing a deal with the BW Group to build two LNG carriers.

The technical engine specification complies with IMO Tier II, with options to include remedies for Tier III compliance at a later stage. The 173,400 m3 vessels are scheduled for delivery in late 2017/early 2018 and will be built at DSME’s Okpo shipyard in Geoje, Korea. The deal represents the second LNG ME-GI contract for DSME after a previous order signed in 2012.

Tier III options

Compliance with IMO Tier III regulations basically requires an 80% reduction in NOx emissions– compared to Tier I– within the designated emission control areas (ECAs) over a defined test cycle.

MAN Diesel & Turbo has successfully developed two main approaches to comply with these challenges:Selective Catalytic Reduction (SCR), which involves the catalytically accelerated reaction of nitrogen oxides with ammonia to form water and nitrogen, and Exhaust Gas Recirculation (EGR), which works by recirculating a portion of an engine's exhaust gas back to the engine cylinders.

Both methods enable compliance with the most stringent of regulations and give the customer the flexibility to choose the solution that suits their individual requirements best, for example, distances travelled within ECA zones as a percentage of total ship usage, different o wnership models or different engine-operation profiles.

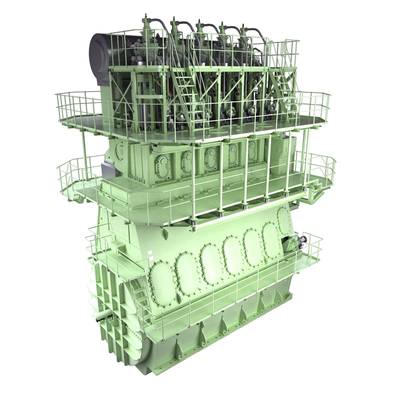

The ME-GI engine

The ME-GI engine represents the culmination of many years’ work and gives shipowners and operators the option of utilising fuel or gas depending on relative price and availability, as well as environmental considerations.

The ME-GI uses high-pressure gas injection that allows it to maintain the numerous positive attributes of MAN B&W low-speed engines that have made them the default choice of the maritime community. MAN Diesel & Turbo sees significant opportunities arising for gas-fuelled tonnage as fuel prices rise and modern exhaust-emission limits tighten. Indeed, research indicates that the ME-GI engine delivers significant reductions in CO2, NOx and SOx emissions.

Furthermore, the ME-GI engine’s negligible fuel slip makes it the most environmentally friendly technology available. As such, the ME-GI engine represents a highly efficient, flexible, propulsion-plant solution. An ME-LGI counterpart that uses LPG, methanol and other liquid gasses is also available, and has already been ordered.

The G-type program

MAN Diesel & Turbo’s G-type program entered the market in October 2010 with the entry of the G80ME-C9 model. The G-types have designs that follow the principles of the large-bore, Mark 9 engine series that MAN Diesel & Turbo introduced in 2006. Their longer stroke reduces engine speed, there by paving the way for ship designs with unprecedented high-efficiency.

Such vessels may be more compatible with propellers with larger diameters than current designs, and facilitate higher efficiencies following adaptation of the aft-hull design to accommodate a larger propeller. It is estimated that such new designs offer potential fuel-consumption savings of some 4-7%, and a similar reduction in CO2 emissions. In this respect, the fuel savings and performance characteristics for propellers featuring MAN Diesel & Turbo’s unique Kappel blade design have been well documented in recent years. Simultaneously, the engine itself can achieve a high thermal efficiency using the latest engine process parameters and design features. As such, the G-type series has revolutionised the marine market. Since its introduction, close to 900 engines bearing the G-prefix have been ordered (including, now, 15 × G95 units), representing a total power output of some 15.9 GW. Of these, over 100 G-type engines have already entered service.