DOD Taps Sea Machines for Autonomous Replenishment Vessels

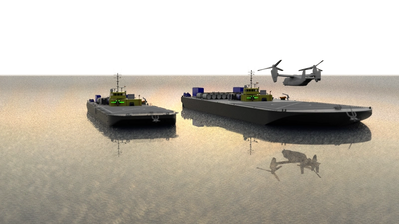

Boston-based Sea Machines Robotics, a developer of autonomous command and control systems for surface vessels, said it has been awarded a multi-year Other Transaction (OT) agreement by the U.S. Department of Defense (DOD)’s Defense Innovation Unit (DIU) to initiate a prototype that will enable commercial ocean-service barges as autonomous Forward Arming and Refueling Point (FARP) units for an Amphibious Maritime Projection Platform (AMPP).

Under this OT agreement, Sea Machines will engineer, build and demonstrate ready-to-deploy system kits that enable autonomous, self-propelled operation of opportunistically available barges to land and replenish military aircraft. The kits will include Sea Machines’ SM300 autonomous-command and control systems, barge propulsion, sensing, positioning, communications and refueling equipment, as well as items required for global deployment. Each modular kit will meet U.S. Navy criteria and will be in compliance with classifications and regulations from the DOD’s aviation bodies.

The contract includes a concept demonstration phase, with an option for following phases to deploy SM300 Operational Kits. The live concept demonstration is scheduled for the fourth quarter of 2020, in Washington state, for which Sea Machines has teamed with Seattle-based maritime transportation and logistics provider FOSS Maritime. FOSS will provide naval architecture, support engineering and operations management to outfit a remotely commanded deck barge to land helicopters and host a scaled fueling station for aircraft, surface vessels and shore replenishment. Using the SM300, shoreside operators will have remote situational awareness and will be able to demonstrate the capabilities of remote command and control of the vessel, her operating systems and flight deck.

Sea Machines is the prime contractor for the multi-year contract and is working alongside FOSS Maritime and others, including Huntington Ingalls, America’s largest military shipbuilding company and a provider of professional services, based in Newport News, Va., and Bell Flight, a producer of commercial and military, vertical-lift aircraft, based in Fort Worth, Texas.

“The AMPP autonomous replenishment systems will solve critical logistics challenges of expeditionary missions. We are pleased to enable this innovative capability, which will increase the effectiveness and flexibility for the U.S. military,” said Sea Machines’ Phil Bourque, director, sales. “With Sea Machines systems already working off the waters of four continents, this project is well suited for us and one that we look forward to delivering on for the U.S. Government.”

“Foss is excited about this new opportunity with Sea Machines. This contract has led to discussions with Sea Machines in a number of other areas where their expertise can help Foss, including bringing more technology to our tug fleet. What they are doing in automation is very interesting and that technology could help our mariners and our vessels safety," said Foss' Will Roberts, chief operating officer.

DIU's work is part of the DOD’s Resilient Expeditionary Agile Littoral Logistics (REALL) Joint Capability Technology Demonstration (JCTD) project. Funded by the Office of the Secretary of Defense Research & Engineering, the JCTD Program addresses Combatant Command (CCMD) and Joint warfighting gaps through prototyping and demonstration of innovative and game-changing technologies. The following offices are involved with defining performance requirements and developing capabilities for REALL: U.S. Central Command, U.S. Transportation Command, U.S. Marine Corps Warfighting Laboratory, Naval Facilities Engineering and Expeditionary Warfare Center, Army Engineer Research and Development Center, and the Naval Aviation Warfare Center - Lakehurst.