DEUTZ Commits to Renewable Mobility

On January 21 and 22, DEUTZ will be attending the 16th International Conference on Renewable Mobility in Berlin, reprising its role as silver sponsor and underlining its commitment to the development of carbon-neutral drive systems.

As well as pressing ahead with the electrification of its engine range under the E-DEUTZ strategy, DEUTZ is working hard to make its products compatible with a choice of sustainable fuels that can be used in its products.

Running engines without using any fossil fuels – and so no carbon either – will be key to achieving the target set by the Intergovernmental Panel on Climate Change (IPCC) of limiting global warming to 1.5 degrees Celsius. For its part, DEUTZ is already on the way to approving the entire latest generation of the TCD engine range for use with alternative fuels (paraffinic diesel fuels and biodiesel blends). The range of paraffinic diesel fuels that are available will in future include ‘e-fuels’, which can be produced on an industrial scale using renewable energy sources and will allow engines to run on a carbon-neutral basis.

From 2019, DEUTZ will also be launching two new LPG engines (DEUTZ G 2.2 and G 2.9) for applications in material handling and compact construction equipment. DEUTZ is thereby diversifying the choice of fuels that can be used in its products and paving the way for synthetic, gaseous e-fuels.

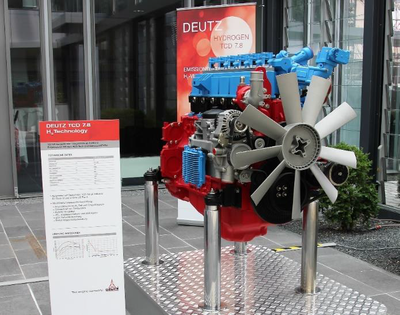

Adapting the traditional combustion engine so it can use hydrogen, which is a sustainable source of energy, is another highly promising area of research at DEUTZ. With the help of DEUTZ, Munich-based start-up Keyou developed a conversion kit that can turn a conventional combustion engine into a drive based on state-of-the-art hydrogen technology. DEUTZ lent its support as a development partner, supplying one of its standard 6-cylinder diesel engines with 7.8 liter capacity (DEUTZ TCD 7.8). The prototype was unveiled in late 2018 at the bauma China trade fair in Shanghai.

In the future, DEUTZ’s modular technology will allow customers to intelligently combine conventional and electric drives and a range of fuel types. Thanks to this modular approach, it will be possible to find the optimum drive system for any application, reducing not only operating costs but also carbon emissions.