ACCuRem Reuses AC Condensate on Cruise Ships

Large cruise ships that sail the warmer regions of the earth such as the Caribbean, the Mediterranean or the Persian Gulf, continuously produce a lot of condensate water. The air is cooled down inside the heat exchangers of the numerous air- conditioning units to a temperature below the dew point of the outside atmosphere. This causes a large fraction of the air humidity to fall out as liquid water (condensate), which accumulates inside the collection pan at the bottom of the air conditioning (AC) units.

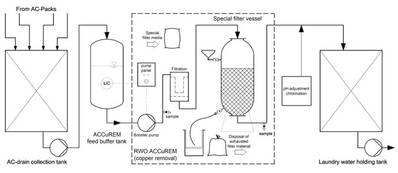

Commonly, the AC condensate of all heat exchangers is collected inside a central condensate tank from where it is used for secondary purposes or pumped directly overboard. What makes the AC condensate interesting for more demanding technical applications is the fact that it is water almost free from salts and minerals. Desalination of water on board a passenger vessel is always a costly process and the by-product AC condensate is available practically "for free." Depending on the outside temperature and the ambient air humidity, the flow of condensate may vary between none at all to up to 20 m3/hr on board very large cruise ships. Keeping in mind its low salinity, this water stream is not negligible from an economical standpoint and the condensate can be use for ship's laundry, which is also a considerable consumer on board.

When the condensate is formed on the surfaces of the air coolers it takes up impurities from the air such as solid matter (dust and bacteria), but also gaseous compounds such as carbon dioxide, NO2 and SO2, as well as copper ions from the AC heat exchangers, which are washed into the AC drain collection tank.

After the first implementations of water-saving concepts on several passenger ships it was seen that the AC condensate led to a special problem. Often the textiles, predominantly the white towels and bathrobes, took on a greenish colour so that they had to be discarded. The green-coloured stains were most likely caused by the residual copper ions that entered the washing machines and precipitated inside the fabrics during washing. This dissolved copper cannot be retained by simple filtration nor can it be removed from the textiles once it has precipitated. The damage thus caused led to the rejection of AC condensate for laundry use and the supply was switched back to normal but expensive potable water.

RWO has developed a solution to this problem together with cooperation partners. The ACCuRem copper removal system is based on a special combination of filtration and ion exchange. Numerous ACCuRem systems are in successful operation on cruise ships since its development and exceeding the expectations of both shipowners and operators.

• Treats several thousands of cubic metres of condensate via a special process

• Very small footprint for easy integration also into existing piping onboard ships

• No requirement to operate or maintain any regeneration equipment

• Easy removal and refill of the filter material

• No other chemicals are involved

• Quickest return of investment costs