BIO UV Unveils New BWTS Series

BIO UV Group said it has designed a new series of BIO-SEA ballast water treatment system (BWTS) compatible with flow rate requirements of up to more than 2,100 cubic meters per hour (m3/h).

The new M-Series BWTS incorporates a novel reactor arrangement designed to increase the flow rate capacity of existing technology without the need for any manifolds.

“This is a huge development in ballast water treatment,” said Xavier Deval, Business Director – BIO-SEA, BIO-UV Group. “With the M-Series we see a significant benefit in terms of size, capacity and installation simplicity. A manifold-free design allows shipowners to optimize installation time and costs dramatically, while keeping the number of reactors required to an absolute minimum; only one or two depending on the required flowrate.”

Deval explained that while the new version is based on the same technology inherent to previous incarnations of the BIO-SEA system, it is the development of the ‘M’ reactor itself that has allowed the company to advance the product.

“The evolution of the BIO-SEA system means ship owners and shipyards now have a high-capacity ballast water treatment system from a unit that incorporates fewer ultraviolet (UV) lamps than competing systems in the market,” Deval said.

“For a 300 m3/h capacity system we can treat the volume with just one two-lamp M02 reactor. For a flow rate of 1,040 m3/h one seven-lamp M07 reactor would do the job, while a pair of these will be able to deal with 2,100 m3/h. With the installation of additional reactors, a maximum flow-rate capacity of 4,000 m3/h can, theoretically, be achieved.”

A range of ‘M’ reactors have been designed for different capacity requirements. These include the M02 for flow rates between 190 and 300 m3/h, the M04 for 500 to 600 m3/h flow rates, the M05 (500 to 750 m3/h), M07 (760 to 1,040 m3/h), M08 (1,040 to 1,200m 3/h), M10 (1,040-1,500 m3/h), and the M14 for 500-2,100 m3/h flow rates.

In effect, BIO-UV Group has together with its own integrated engineering department developed a downscaled version of its existing UV technology to reduce system footprint and integration costs by at least 25%.

All environmental testing and UV dosage tests have been done under DNV supervision. International Maritime Organization (IMO) and U.S. Coast Guard (USCG) certification documents are imminent.

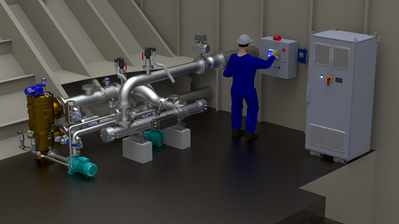

Available as a modular or skid system and with fewer components resulting in a reduced risk of corrosion, the M-series is available with a short lead time. A number of units are already on the shelf for immediate delivery.

BIO-UV Group said it will continue to manufacture and support the BIO-SEA B-Series, noting there are components and spare parts common to both treatment systems.