Autonomy: Inside the Building of Ocean Infinity’s Armada Fleet

Back in 2017, Ocean Infinity made a novel move; deploying six autonomous underwater vehicles (AUVs), instead of just one, from a single vessel, vastly increasing the ground that could be covered in a single survey. Now the firm is taking the use of remote, robotic systems a significant step further.

Back in 2017, Ocean Infinity made a novel move; deploying six autonomous underwater vehicles (AUVs), instead of just one, from a single vessel, vastly increasing the ground that could be covered in a single survey. Now the firm is taking the use of remote, robotic systems a significant step further.

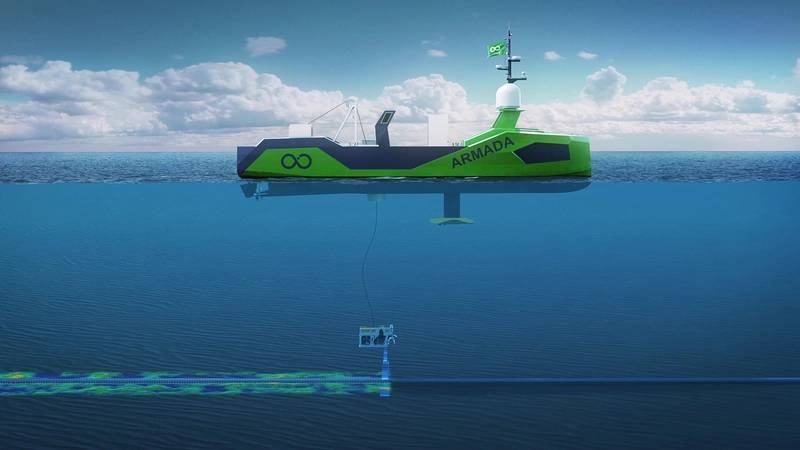

As we enter 2021, US-UK based marine robotics firm Ocean Infinity is launching the start of what will become a fleet of completely uncrewed ocean going vessels, or USVs. They will host and deploy other robotic systems, including remotely operated vehicles (ROVs) and AUVs, as well as towed systems and full ocean depth survey equipment. The first two in what’s being called the Armada fleet will be launched early next year ready for commercial operations in the North Sea in summer 2021 and an initial 17 are planned.

The company has brought some known experience onboard, including Dan Hook, who was behind the UK’s ASV Ltd., an early developer of USVs now owned by L3Harris. What we realized, Hook says, is that small USV systems could only do so much so, while there was take up in the defense sector, for mine and submarine hunting, other sectors were slower to adopt such systems beyond inland, lake or coastal surveys.

“One of the limitations we observed in existing USVs was that you could only really deploy one type of sensor or go out for a week at a time,” he says, which meant they could only do so much. “In building Armada, we really tried to address that. The biggest change is scale. A 21 m vessel can carry multiple sensors, the right type of ROVs and the right type of sensors and winches that customers need.”

The initial vessels will come in at 21 m and 36 m long. All will come with a standard fit of permanently mounted survey equipment, mostly housed in a subsea gondola. This will include an inertial navigation system (with integrated acoustic Doppler current profiler/Doppler velocity log), single beam echo sounders, underway conductivity, temperature and depth (CTD), Ultra-Short BaseLine (USBL) positioning, and dual-head shallow-water multibeam echosounder and sub-bottom profiler.

Modular payloads will be added on top. Initially, that will be ROV focused, ranging from Saab Seaeye Leopards, recently ordered for the fleet, to Ocean Infinity’s existing Schilling and Kystdesign hydraulic ROV systems designed for 3,500-4,000 m water depth. All of them will be deployed and recovered by an all-electric, automated vehicle-agnostic system being supplied by Kongsberg – so it’ll be able to deploy different ROVs, as well as AUVs. The system will deploy vehicles via the vessel moon-pool, with release and capture of the ROV/AUV below the surface, away from the vessel hull to avoid potential vessel impacts and allow for higher sea-state launch and recovery.

Image Courtesy Ocean Infinity

Image Courtesy Ocean Infinity

Some vessels will be able to take two vehicles on board, to provide flexibility but also redundancy, says Michael King, business development manager at Ocean Infinity. “We’re also going to be able to tow various hydrographic and geophysical sensors, towed side scan sonars, magnetometers,” he says.

The firm has a wide range of potential work in its sight, from survey to UXO capability for the offshore wind market, 2D and 3D seismic, oceanographic and metocean data acquisition and geotechnical capability. It’s already working on a full ocean depth deep water multibeam system for the larger vessels, targeted at the subsea cable market. The vessel’s endurance will make long surveys easily feasible. At cruising speed it’s expected the 21m vessel will be able to travel 3000 nm and the 36m vessel 5500nm. More vessels will come and inevitably they will be bigger again, as the firm eyes additional opportunities, such as logistics, in addition to the survey, ROV and AUV operations down to 6,000 m it will target first. They’ll also be looking to add aerial drones in the future.

“We’re looking at a wide spectrum of applications,” says Hook, “everything from survey, collecting data, through inspection, logistics, defense and security and we’ve had a lot of enquiries in each, with a lot around data collection and inspection, especially from wind farm, offshore energy and cables – telecommunications and power.”

It’s also been revealed that the firm is working with Shell to be able to run multiclient seep hunting projects, using AUVs deployed from the USVs, which could then support work like carbon capture and storage site monitoring.

The hardware is one thing, but remotely operating uncrewed systems also relies on communications, to be able to control the systems, and data transfer – as much of their work and the management of it is about getting data. There are a few sides to that; managing it on the vessel, managing delivery of it and then managing it at a remote control center (ROC). The first has Ocean Infinity working with various data management providers and software companies to ensure data quality, with pre-processing offshore so not all raw data needs to be sent to shore. Cyber security comes into this and the company has employed experts, including an ex-US Air Force cyber expert, and has designed the vessels from the outset with cyber security in mind.

“In the next few years we would expect our road map to take us to one mariner supervising two of these vessels or maybe even three.”

“In the next few years we would expect our road map to take us to one mariner supervising two of these vessels or maybe even three.”

Michael King, Business Development Manager at Ocean Infinity

Then, to enable remote control, each vessel will have two large satellite domes, in addition to VSAT and 3-5G communications capability. “You can miniaturize everything you want in robotics these days; you can make tiny computers and tiny computers,” says King, speaking at the joint Hydrographic Society, IMCA, SUT seminar. “But the one thing you can’t miniaturize is a satellite dish and the truth is a larger satellite dish gives you more bandwidth. Because we have larger vessels than traditional USVs we can mount 2-3 large domes on each and that enables us to have larger bandwidth, in turn enabling us to have true command and control and data transfer in real time, bringing everything back to a ROC where a team of experts is sorting out the data management.”

While autonomy is regularly talked about, today’s vessels will not be autonomous, says King, each will have a mariner in control – “full human in the loop”. But it’s expected that autonomy will come. “In next few years we would expect our road map to take us to one mariner supervising two of these vessels or maybe even three,” he says.

As these systems go out into the wild, a challenge could be physical security – what’s to stop the vessels being attacked? This is new ground, says Hook. But, again, the vessels are being designed to prevent such an event. For a start, they’ve a mode to move and keep away from a threat automatically, then they’re hard to board and the decks locked down, he says, and there’s nothing to steal, or people to ransom, which has been a driver for past piracy events. Ocean Infinity is also looking at CCTV and an onboard PA system as well. But this will be a case of learning, as in any new business, and it’s an area Hook says the company is keen to work with industry jointly on.

Another area that will develop is berthing. Unlike past USVs, these vessels will not be able to be put on a trailer and driven to a port for deployment. In some cases they’ll be able to sail into a port or harbor themselves (under remote pilot control), where local suppliers could support refueling. In busier waters, a crewed pilot vessel would come out and escort the USV into port. The company will also have a field team, to go out and support berthing, says Hook.

“In building Armada, we really tried to address that. The biggest change is scale. A 21 m vessel can carry multiple sensors, the right type of ROVs and the right type of sensors and winches that customers need.”

“In building Armada, we really tried to address that. The biggest change is scale. A 21 m vessel can carry multiple sensors, the right type of ROVs and the right type of sensors and winches that customers need.”

Dan Hook (Photo: Ocean Infinity)Initially, operations will be in UK waters with work already lined up in wind farm, oil and gas and the subsea cable sectors in the first year, says Hook. These will be managed from a new operations center the company is building in Southampton. Ocean Infinity, which currently has offices in the UK and Austin, Texas, aims to open a third in Asia, and is also actively looking where else to deploy its fleet, from Australia to Taiwan and America.The Covid pandemic has helped generate interest, says Hook. “When looking at risk planning for the future of their business, future pandemics is now on everyone’s lists,” he says. “The risk of moving crews around the world and on and off of ships means uncrewed operations have definitely come to the fore.”

The initial British flagged DNV GL class fleet is being built at the Grovfjord Mek. Verksted (GMV) yard in Norway. But Hook says future vessels are likely to also be built elsewhere and the company is already in talks with yards in the US, where they would be Jones Act compliant. The vessels have a hybrid-electric propulsion system, with Volvo Penta DC gensets and Danfoss DC grid control system, with high battery capacity to enable more electric and even all-electric operations where possible. Hook says other cleaner fuel options could also be considered in the future, as options mature. Even with the hybrid system could save 90% emissions compared with a conventional 65m-long offshore vessel, at 644,182 kg CO2 versus 31,101 kg for an Armada vessel, based on trials assessing a typical 21-day offshore campaign, says King.

As the company is breaking new ground (or water) in this area, it’s going in ‘eyes wide open’, says Hook, from the physical security to berthing and regulations. “We are working with as many different people as we can, the MCA, US Coast Guard and other international governance bodies towards safe operation of larger uncrewed vessels,” adds King. “We’re working with DNV GL as class society and we’re particularly grateful for the support from IMO and MSC meetings.” The company is also part of Maritime UK and IMCA working groups and other steering groups. But, “what we need to get across is regulations have to be fit for purpose, but they also have to serve the industry as well to allow for the advantages of systems to be utilized,” says King.

Meanwhile, the company is staffing up. That means recruiting people, from master mariners to specialists in cyber awareness and remote engineering. It’s offering new job opportunities says Hook. And it’ll soon be a norm, he says. “Right now, it feels new and novel. But in 5-10 years this is going to feel very normal,” he says.

Meet Armada

US-based seabed survey and ocean exploration company Ocean Infinity said it has launched a new marine technology and data company boasting the industry's largest fleet of unmanned surface vehicles (USV).

Armada, with a focus on combining technology and environmental sustainability, will initially add 15 bespoke designed marine robots to Ocean Infinity’s current fleet of autonomous underwater vehicles (AUV).

Armada’s fleet is currently under construction and is expected to be deployable by the end of 2020.

Each unmanned surface robot will serve a wide range of industries by being fully equipped to perform a multiplicity of offshore data acquisition and intervention operations down to a depth of 6,000 meters. These robot ships will be capable of remotely deploying a wide range of the latest sensors as well as AUVs and remotely operated underwater vehicles (ROV) for visual and acoustic data acquisition.

Armada’s fleet requires neither people on board nor a host vessel nearby. Instead they will be controlled and operated by experienced mariners via satellite communications from state of the art onshore facilities in both Austin, Texas and Southampton, England.

The fleet approach produces up to 90% less CO2 than other conventional survey vessels, Ocean Infinity said.

Oliver Plunkett, CEO for Ocean Infinity, said, “We’ve been driven to innovate by a desire to further reduce our impact on the environment and the time people spend at sea. We have built an outstanding team who boast world leading expertise to take this next stage of our business forward for the benefit of our clients and all those who work with us ”

Dan Hook, Managing Director for Armada, said, “We are very excited to be launching Armada, which perfectly complements the other service offerings in the Ocean Infinity Group. The pioneering technology makes our operations world-leading in terms of environmental sustainability and safety, while still achieving the very highest levels of data quality and value for our clients. With no requirement for a host vessel, we are breaking new ground in the area of subsea technology and data.”