Aiming for Zero Waste Discharge to Sea

Advanced water treatment systems are just the start of the cruise industry’s circular waste processing ambitions.

Advanced wastewater treatment systems (AWTS) were revolutionary in their day. Indeed, they still are today, but with 77% of the CLIA fleet (202 ships) already using them, and another 40 specified for vessels on order, even more ambitious waste management is coming.

Martin Shutler, Principal Engineer, Product Development, at Wärtsilä Water and Waste, notes that in recent years the specifications for most newbuild cruise ships have included the requirements for ‘zero discharge’ and a sewage effluent quality that meets the more stringent discharge requirements set for the Baltic Sea and Alaska. In these cases, all black and grey wastewater streams produced on board (including food waste reject water) are required to be treated in an AWTS in accordance with MEPC.227(64) including removal of nutrients such as ammonia, nitrogen and phosphorus as specified in paragraph 4.2.

In practice, this has meant systems with significantly higher treatment capacities to handle the larger volume of influent produced by including gray water as well as black water and careful consideration of membrane bioreactor (MBR) design to ensure the biological load is treated to the required standard, says Shutler, adding that the Wärtsilä MBR technology produces compliant effluent samples to the highest standards.

Even with existing regulations, there is a noticeable absence of formal oversight for monitoring compliance with sewage and grey effluent discharge. Martin Sanders, MD, Rivertrace. Image courtes Rivertrace

Even with existing regulations, there is a noticeable absence of formal oversight for monitoring compliance with sewage and grey effluent discharge. Martin Sanders, MD, Rivertrace. Image courtes Rivertrace

Gray water has long been an area of concern, as unlike black water, it is largely unregulated at present. The IMO is looking at greater regulation with its current review of MARPOL, and regulations to ensure that gray water is treated prior to discharge are expected.“While some jurisdictions, like the US, have implemented laws mandating large cruise ships to adopt AWTS for both greywater and sewage, substantial regulatory gaps persist,” says Martin Saunders, Managing Director of Rivertrace. “Even with existing regulations, there is a noticeable absence of formal oversight for monitoring compliance with sewage and grey effluent discharge.”

This lack of monitoring poses considerable challenges in evaluating the effectiveness of onboard treatment systems, leaving operators uninformed about their vessels' environmental impact, says Saunders. Some OEMs also express concern about the prevalence of 'cheap and cheerful' treatment plants that may prove ineffective over time.

While, AWTS generally operate to a higher standard than many shoreside treatment plants, the EU also sees compliance gaps. Ships in EU seas should face dissuasive fines, not only for oil spills, but for sewage and garbage discharge as well, said the Parliament’s Transport and Tourism Committee in November 2023. A new regime is planned.

Cruise lines are already addressing the risks posed by their older vessels. Scanship has a major retrofit project underway for a system capable of processing all wastewater generated by 6,000 individuals. The Scanship system handles black water, gray water, galley gray, laundry gray, dryer reject, bio residue reject and food waste reject.

The Scanship AWTS is designed to handle all generated wastewater from the hotel area.

The Scanship AWTS is designed to handle all generated wastewater from the hotel area.

Photo courtesy VOW Scanship

With these varied sources covered, the industry is directing its attention to solid waste and dewatered sludge. A ban on sewage sludge discharge is also expected from the IMO’s MARPOL review. This sludge is typically discharged overboard untreated. However, most new zero discharge cruise ships specify equipment for dewatering and drying this sludge (similar to food waste).

Wärtsilä’s range of zero discharge systems includes a Micro Auto Gasification System that diverts dewatered waste from overboard discharge or incineration and converts it to syngas in a circular process that fuels the unit. This has been installed on Silversea Cruises’ LNG-fuelled Silver Nova, delivered in 2023.

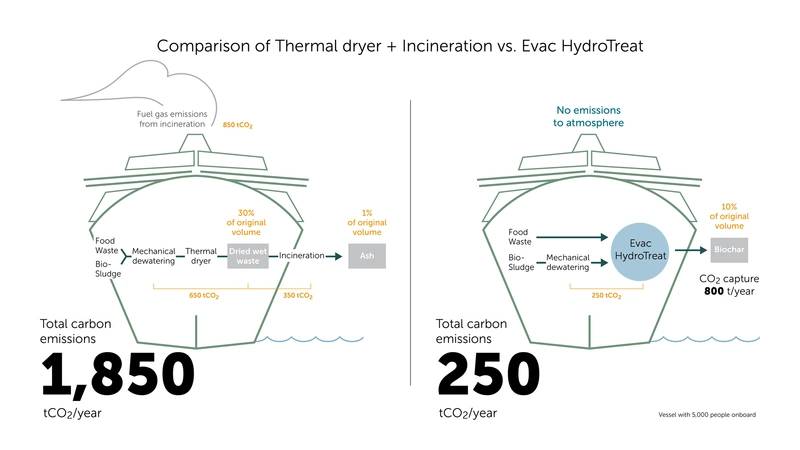

Evac is looking to the future use of nutrients as part of its commitment to a circular economy. The newly released Evac HydroTreat turns de-watered organic waste from black/gray water and food waste systems into biochar that is sterile and can be used for soil improvement or biofuel. The company guarantees significantly lower carbon emissions compared to conventional drying and incineration systems with no harmful emissions into the atmosphere, as there is no need to combust the waste. First orders of the technology have been delivered; it is also retrofittable. Evac HydroTreat turns de-watered organic waste from black/gray water and food waste systems into biochar.

Evac HydroTreat turns de-watered organic waste from black/gray water and food waste systems into biochar.

Image courtesy Evac

Björn Ullbro, CEO of Evac Group, explains: “According to our recent study, the waste recycling rate on some of the world’s largest vessels is around 20-40%. That means the vast majority ends up in landfills or, even worse, in the already threatened oceans.” He says a recycling rate of 70% is technically and commercially feasible with today’s technology.

Engineering processes continue to be improved. Valentin Kirsch, Area Manager for Advanced Wastewater Treatment at RWO, says that the CleanSewage Membrane Reactor (CS-MBR) system’s submerged ultrafiltration membranes remove solids including bacteria, viruses and microplastics. Additionally, the system does not involve the use of flocculants or chemicals for disinfection.

“This is a feature that is unique to the CS-MBR and contributes to its sustainability profile as not only does it ensure the highest effluent standards, but the treated water is clean enough to be re-used in technical water applications,” says Kirsch. This includes the water used in the CS-MBR itself. The system has been installed on five Celebrity Solstice-class vessels, and has now been chosen by KiwiRail for two ropax ferries.

RWO’s CS-MBR system remove solids including bacteria, viruses and microplastics.

RWO’s CS-MBR system remove solids including bacteria, viruses and microplastics.

Image courtesy RWO

The issue of discharging plastic into the ocean is not new. Plastic cups and straws can end up in food waste that is allowed to be discharged untreated out to sea at most locations. Power Knot food waste systems can trap that plastic and prevent its discharge. President Iain Milnes started working with Carnival Corporation 10 years ago on the management of its food waste stream. Most recently, that relationship has meant that Cunard’s Queen Anne will have 26 Power Knot systems installed when launched in 2024.

The company’s LFC biodigesters weigh the amount of waste that is ingested and report that on the cloud by the hour, day, week, month and year. Larger models can categorize waste by type or by source. For example, they can detail how much fruit, meat, or vegetables were ingested and which galley produced the waste.

“Fish don’t eat steak pie and chips as part of their natural diet, and what’s not eaten will decompose anaerobically creating methane and polluting the sea,” says Milnes. He hopes the IMO will move quickly on preventing the discharge of untreated food waste overboard and that MARPOL will be changed accordingly, sooner rather than later. Cunard’s Queen Anne will have 26 Power Knot systems installed.

Cunard’s Queen Anne will have 26 Power Knot systems installed.

Image courtesy of Power Knot.