U.S. Coast Guard Accepts Nine BWTS as AMS

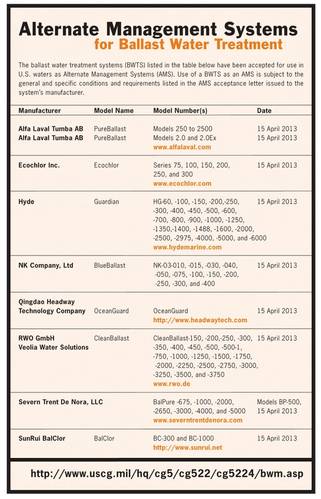

Followers of the Ballast Water Treatement System (BWTS) situation (ie. presumably anyone reading this publication) were heartened last month when the U.S Coast Guard announced its acceptance of nine BWTS as Alternate Management Systems (AMS), helping to finally bring some clarity to ship owners, yards and suppliers.

On April 15, 2013, the USCG announced the acceptance of the ballast water treatment systems as AMS in compliance with the service’s March 2012 final rule for Standards for Living Organisms in Ships’ Ballast Water Discharged (SLOSBWD) in U.S. waters. AMS acceptance by the Coast Guard is a temporary designation given to a ballast water treatment system approved by a foreign administration. Vessel operators may use an AMS to manage their ballast water discharges in lieu of ballast water exchange, while the treatment system undergoes approval testing to Coast Guard standards.

An AMS may be used to meet the Coast Guard ballast water treatment requirements for up to five years after the ship’s ballast water discharge standard compliance date specified in the final rule. This five-year timeframe allows for the completion of required land-based and shipboard testing. “This is an important first step in making Coast Guard and foreign approved ballast water treatment systems available for the global shipping industry,” said Coast Guard Rear Adm. Joseph A. Servidio, Assistant Commandant for Prevention Policy. “The Coast Guard AMS program will allow ship owners and operators to install a ballast water treatment system and use it in U.S. waters while it undergoes approval testing.” In the following pages, Maritime Reporter & Engineering News presents information on the many of the systems currently accepted as an AMS

Alfa Laval: PureBallast

PureBallast was among the first ballast water treatment systems to receive Ballast Water Type Approval. Operating under real-life conditions since 2003, PureBallast provides ballast water treatment that is 100% chemical-free. The process is based on a patented form of advanced oxidation technology (AOT), developed in cooperation with Wallenius Water. Treatment occurs in a closed chamber known as a Wallenius AOT unit, in which radicals are generated. These radicals are potent yet exist for only a few milliseconds, which means they neutralize microorganisms but are incapable of leaving the treatment system. A 40 μm mesh filter is used during ballasting operations. This blocks the intake of larger organisms, but also reduces the amount of sediment in the ballast water tanks. The number of AOT units is determined by the system’s flow rate, with individual units handling a flow of 250 cu. m./hr. The performance of the AOT units is safeguarded by an automatic Cleaning-in-Place (CIP) system, which circulates a biodegradable solution to prevent seawater scaling within the AOT units. This solution is reusable and is replaced once annually when its pH level becomes too high. The automatic cleaning cycle occurs after each operation. The filter is also rinsed once ballasting is completed. A flow meter regulates the certified flow rate and records the volume of ballast that been treated. The water then continues through the AOT units, which treat the water to IMO established limits before it enters the ballast water tanks. The de-ballasting process is the same as ballasting, but bypasses the filter system (which is cleaned via automatic back-flushing). Outgoing ballast water passes through the Wallenius AOT units to eliminate any re-growth of microorganisms that may have occurred.

A single PureBallast system can handle flow rates of 250-3000 cu. m./hr. If more capacity is required, even higher flow rates can be achieved by installing multiple systems in parallel. Sold to all vessel types, container vessels, RO/RO and pure car/truck carriers account for about one-third of all units sold. For Alfa Laval, the 250 to 2,000 cu. m./hr. sector is strongest target market. Alfa Laval has achieved IMO Basic and Final approvals as well as Type Approval from DNV.

Ecochlor Inc.: Ecochlor

Ecochlor, Inc. received U.S. Coast Guard Alternative Management System (AMS) acceptance for its full line of ballast water management systems (BWMS). This will allow ship operators to use an Ecochlor ballast water management system in U.S. waters to effectively manage their ballast discharges.

“We are pleased to be among the first group of companies to receive AMS acceptance,” said Charlie Miller, Chairman and CEO of Ecochlor. “An AMS determination offers ship owners an additional level of security and assurance that the efficacy and performance of Ecochlor’s ballast water treatment systems will meet both present and future discharge standards throughout the world.”

Ecochlor, Inc. received Product Design Assessment (PDA) Approval from ABS for its full range of ballast water treatment systems (BWTS), systems that have the capacity to treat ballast water flow rates of up to 16,000 cu. m./hr. The Ecochlor BWTS uses a two-step process to treat ballast water – filtration followed by disinfection with the well-known biocide, chlorine dioxide. The system’s effectiveness is not impaired by variations in salinity, temperature, turbidity, organics and vibration, which can impact other treatment options. Furthermore, the small size, low power, and low maintenance characteristics of the Ecochlor system make it ideally suited for installation on the world’s largest ships. Compatibility with explosion protection specifications also allows the Ecochlor system to be easily installed on tankers.

Prior to ABS PDA Approval, the Ecochlor BWTS received IMO G9 Final Approval in September 2010. The Ecochlor BWTS has IMO Type Approval from Germany (BSH), as well as Type Approvals from the Liberian Administration. Ten consecutive test cycles on land and aboard ship over a two-year period resulted in no surviving organisms after treatment. With testing results of all zeros, it proved that the system could meet or exceed proposed U.S. requirements of at least 10x IMO standards. This completed the international approvals of all of Ecochlor’s Systems and confirms that they fully comply with the 2004 IMO International Convention for the Control and Management of Ship’s Ballast Water and Sediments.

Ecochlor holds a unique position in the shipping industry as using patented chlorine dioxide (ClO2) treatment technology for ballast water. There is an exclusive distribution agreement with EKA Chemicals (part of the Akzo Nobel group of companies) for the EKA ClO2 generation technology for use in the marine and shipboard environment. Key system advantages are touted as small size, low power and low maintenance characteristics.

Headway Technology Co., Ltd.: OceanGuard

OceanGuard Ballast Water Management System (BWMS), developed and manufactured by Headway Technology Co., Ltd., has proven its value with references aboard some of the largest, highest value and conspicuous ships on the world’s waterways: luxury cruise ship. OceanGuard was recently installed onboard Aida Stella, a Carnival cruise vessel. Aida Stella is the first order and application in Germany for Headway, and is the second luxury cruise vessel order from Carnival Corporation, as Headway reached its first cooperation with Costa Crociere S.p.A, Italy on July 26, 2011.

After that, Headway signed agreements for the BWMS projects for oil tankers from Greece, Norwegian multi-purpose vessels and barges, as well as the Singapore offshore operating company POET.

On Aida Stella, installation and commissioning of OceanGuard BWMS was finished in Papenburg, Germany, and the ship was scheduled to be launched early March 2013. During the installation, representatives from Aida Stella/Carnival spoke highly of OceanGuard BWMS for its compact design and easy installation.

Hyde Marine

Hyde produced its first system in 1999 and installed its first system on the M/S Coral Princess in 2003. The Hyde system was the first accepted into USCG STEP program in October of 2008.

With more than 225 BWT systems already sold into the marine markets via about 180 ships, Hyde is well known in blue water shipping as a top tier provider of BWT solutions. But, Hyde has also sold as many as 75 systems to Offshore Supply Vessel (OSV) owners and also sells to a myriad of other smaller platform operators as well.

Hyde’s Guardian features a two-stage process; stacked disk filtration to remove sediment and larger organisms, and a UV disinfection unit to kill or inactivate smaller plankton, bacteria and other pathogens. During ballasting, water is processed through both filter and UV stages. All captured solids and organisms are discharged during back flushing to the location they entered. During de-ballasting, the filter is bypassed and water flows only through the UV system before discharging overboard. Hyde Guardian system and ballast operation data are automatically logged.

Hyde Guardian uses a high intensity ultraviolet (UV) treatment as a means of disinfection. The UV chamber is designed for minimum pressure drop, maximum retention time, and compatibility with the marine operating environment. The medium pressure lamps produce a polychromatic output across the entire spectrum of the germicidal curve and have an expected service life of up to 8,000 hours.

The Hyde Guardian Ballast Water Treatment Systems have IMO Type Approval for capacity from 60 to 6,000 cu. m./hr., and a Type Approval Certificate has been issued by Lloyd’s Register on behalf of the U.K. Maritime and Coastguard Agency to confirm compliance with Guidelines contained in IMO resolution MEPC.174(58). Other certifications include ABS, Dutch Flag State, Russian Maritime Registry of Shipping, DNV (Hazardous Area Certification) and DNV EC-Type Examination Certification.

RWO: CleanBallast

As one of the first ballast water treatment systems, RWO’s CleanBallast has received the AMS approval. “The AMS is a very important certificate for us,” said Martyn Ayris, MD, RWO. “Being chosen by USCG as one of the first companies to receive it again confirms the technical refinement of our CleanBallast system and demonstrates that our two-stage treatment concept with its advanced process steps is a mature technology - providing the necessary reliability to make owners and their fleets ready for future challenges.”

The AMS approval is just the latest success in a series of achievements RWO accomplished in the past months. In the course of 2012 many owners demonstrated confidence in the CleanBallast technology and selected the system for newbuilds, as well as for retrofits. In September the Bremen-based manufacturer also received Product Design Assessment (PDA) Certificate from Germanischer Lloyd for its ballast water treatment system. To date the CleanBallast technology has already been selected by customers from Belgium, China, Canada, Cyprus, France, Germany, Hong Kong, Japan, South Korea and the Netherlands for a variety of vessels including container, bulker, heavy lift, RoCon, multi-purpose and tankers.

Seaspan caused a stir when it showcased its revolutionary SAVER (Seaspan Action on Vessel Energy Reduction) design of 10,000 TEU container vessels. Pursuing the aim of top-efficiency ship operation and improved operational performances, Seaspan has decided to equip its Saver class vessels with RWO’s ballast water treatment system CleanBallast. The delivery of the first plant to China’s Jiangsu New Yangzi shipyard was set for March 2013.

The CleanBallast technology gained official type approval from the German BSH in 2010, and was submitted for AMS and USCG approval in mid-2012. At last year’s SMM exhibition, RWO officially launched a modified version of the system, based on the technology but using considerably less footprint.

The treatment principle is based on two cleaning steps, consisting of the removal of sediments and bigger particles by self-cleaning deep-filtration disc filters followed by a disinfection step using RWO’s patented EctoSys technology eliminating the remaining bacteria and organisms.

Severn Trent De Nora: BalPure

The IMO Type-Approved Balpure ballast water treatment system from Severn Trent De Nora has become one of the first ballast water treatment technologies to receive the United States Coast Guard’s (USCG) Alternate Management System (AMS) certification. The AMS certification has specifically approved the use of Balpure, which complies with IECEx Classification, in hazardous areas on board vessels. Severn Trent De Nora has sold and delivered 20 Balpure units since it received its IMO Type Approval in July 2011. “The Balpure team has been working tirelessly to obtain the various approvals required for the system to be accepted for use on board international trading vessels,” said Marwan Nesicolaci, VP, global sales and marketing, Severn Trent Services.

“This new AMS certification of Balpure is a significant milestone for us as it signifies the system is now permitted to be used on board vessels trading in U.S. waters that are required to comply with the USCG Final Rule.

This achievement solidifies Balpure’s position as a robust and reliable solution that shipping companies can trust.”

As part of the USCG’s extensive review process for AMS, Severn Trent De Nora submitted: basic approval documentation, final approval documentation, shipboard test data, Operations & Maintenance manual, detailed drawings for each Balpure System (flow sheets, P&ID, general arrangement), and Bill of Materials (BoM) for each system including vendor technical literature and certification for all equipment.

Balpure features proven electrolytic disinfection technology, ease of installation and operation, minimal maintenance and low operating costs for both retrofits and newbuilds. Its slip stream treatment approach, where approximately one percent of the total ballast water flow is used to generate the hypochlorite disinfection solution, enables remote mounting away from the main ballast line. The slip stream treatment approach, coupled with a design that requires treatment only during the uptake of the ballasting cycle, offers significantly reduced power requirements when compared to competing technologies – ensuring low operational costs. Balpure offers a virtually maintenance-free approach to ballast water treatment through the use of proprietary self-cleaning electrodes that eliminate the need for time-consuming chemical and mechanical maintenance

(As published in the May 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)