ABS and Pelagus 3D to Advance Additive Manufacturing for Spare Parts

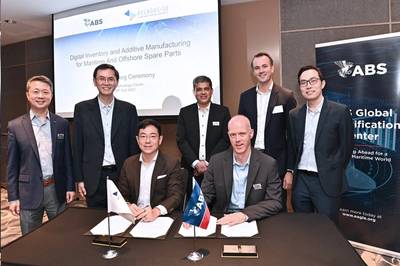

ABS and Pelagus 3D Pte. Ltd., a joint venture company of thyssenkrupp and Wilhelmsen, signed a memorandum of understanding (MOU) to advance the technologies and adoption of on-demand additive manufacturing (AM) of marine and offshore spare parts.

During a three-year term, ABS and Pelagus 3D will collaborate on a variety of initiatives including the incorporation of ABS testing requirements through the Pelagus Platform for AM parts. This project will also support the continued development of industry guidelines and standards for AM, including qualification of global AM manufacturers and streamlining of certification for AM parts.

“AM technologies have the potential to streamline supply chains and simplify procurement and maintenance schedules, minimizing delay and reducing costs. ABS is committed to supporting continued innovation in the development of AM technologies through industry-leading projects, such as this one with Pelagus 3D, and through our approval and certification process, while maintaining our focus on quality and safety,” said Gareth Burton, ABS Vice President of Technology.

The MOU was signed in Singapore during the ABS Technology Forum: Enabling Electrification and Model-based Approaches, a conference connecting key stakeholders across the maritime value chain. Attendees from manufacturing, government and academia joined ABS to identify areas for future collaboration and research projects.

“At Pelagus 3D, we believe in pushing the boundaries of innovation to create a more resilient and efficient spare parts supply chain. The MOU signing with ABS marks a pivotal milestone for the growth of the AM spare parts supply chain. We look forward to working together with ABS to enhance testing capabilities that will ensure seamless integration and accelerate adoption of AM in the maritime and offshore industry,” said Kenlip Ong, Pelagus 3D Chief Executive Officer.