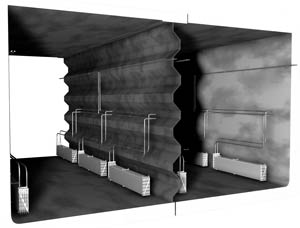

PLATECOIL based cargo heating system in articulated tug barges. Please note the drawing is not to scale; banks and piping are enlarged for clarity. |

|

|

Operation and Durability—PLATECOIL banks are not susceptible to flow-induced vibration, vibration-induced fatigue cracking, and waterhammer from condensate blocking. Although they constitute a more compact design, they offer superior baffling performance in active seaways. Simple Installation—PLATECOIL banks are assembled into a rigid, integral unit comprised of: - Manifold connections

- Support and stiffening structures

- Integral feet for elevating the PLATECOIL bank off the deck

Case Study: PLATECOIL vs. Pipecoil Installation

Consider a 155,000-barrel ABS Classed ocean going tank barge containing 10 cargo holds with a capacity of 651,000 U.S. gallons per hold: PLATECOIL Installation May Reduce

• Material and labor costs

• Vessel weight

• Expansion tank size

• Heat transfer area

• Heat transfer oil volume

- Reduces weight of oil on vessel

- Lowers initial fill cost

- Lowers disposal cost |

Pipecoil installation would have required 23,349 linear feet of schedule 40 Pipecoil to properly heat the holds. PLATECOIL installation required a total of 40 PLATECOIL banks, four banks per hold. Each bank consisting of two 304L stainless steel PLATECOILS measuring 22” x 143”. The compact, efficient design of the PLATECOIL heat exchanger significantly reduced labor costs, decreased vessel weight, and reduced thermal oil volume. The overall efficiency improvement in these areas helped reduce the initial capital investment for the 155,000-barrel tank barge by $667,000. R.W. Fernstrum is the exclusive North American marine dealer for Tranter, Inc. Contact our sales and engineering team or visit fernstrum.com to learn more about the PLATECOIL Prime Surface Heat Exchanger – the right technology for cargo heating. |

Read the Magazine

Read the Magazine