Westinghouse Marine Division To Supply Sealift Propulsion System Components Submergible Deck To Recover Oil

Westinghouse's Marine Div. in Sunnyvale, Calif, has made a committed entry into the U.S. Navy's Strategic Sealift propulsion market by positioning itself to supply propulsion components as well as complete propulsion systems.

Westinghouse officials said the company is making this long-term commitment to meet the future requirements of its propulsion customers by teaming with several of the world's leading marine propulsion component suppliers and by choosing New Orleans, La., as the site for a new state-of-the-art diesel engine assembly and test facility.

"These agreements and the new assembly and test facility position Westinghouse as a high-quality U.S. source for propulsion components and complete propulsion systems, including diesel engines, reduction gears, line shafting and controllable pitch propellers," said Jack Orme, Westinghouse Marine Div. Diesel Propulsion manager. "And these capabilities allow us to help shipyards be more competitive." Westinghouse has teamed with New Sulzer Diesel Ltd. of Winterthur, Switzerland to market and manufacture low-and mediumspeed diesel engines in the U.S., and with Sulzer Escher Wyss of Ravensburg, Germany, for controllable pitch propellers. Westinghouse will supply reduction gears from its Sunnyvale facility. The agreement with Sulzer Escher Wyss also includes Jorgensen Forge of Seattle, Wash., an experienced source for the forging and machining of shafts, shaftline components and other equipment.

Westinghouse is a world-class designer and manufacturer of complete ship propulsion systems, and in recent years has been selected by the U.S. Navy to design, develop and produce the next generation of efficient gas turbine engines for navy surface combatant ships, as well as the advanced propulsion systems for its two most recent submarines, the Los Angeles and Seawolf classes. In addition, Westinghouse-built reduction gears drive more than 100 Navy ships, including destroyers and cruisers. The company has designed and manufactured propulsion turbines, reduction gear sets, control systems and turbine generator sets for ship electrical service for most of the century.

"These systems offer high reliability, long intervals between overhauls and low fuel oil consumption, which translates into low operating costs," said Mr. Orme. "Operators will reduce long-term costs as well when factors such as system reliability and operating life are taken into account." Westinghouse plans to manufacture major components such as cylinder liners, pistons, rods, heads, valves and other equipment for these engines in its Sunnyvale, Calif, facility, and assemble and test the completed diesel engine system at a new 200,000-sq.-ft. diesel marine propulsion assembly and test facility in New Orleans. The new facility is scheduled to become operational in early 1995, in time to meet delivery requirements for new construction Sealift ships.

"This facility makes it possible for complete low- and medium-speed diesel engines to be delivered by barge directly to shipyards without the need for extensive disassembly and reassembly," Mr. Orme said. Westinghouse intends to market and manufacture Wyss model.

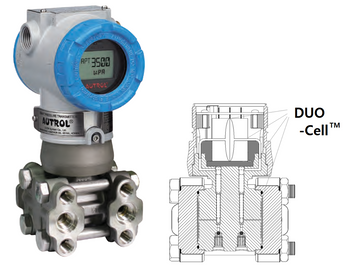

"This new site provides a major advantage to shipyards because it significantly reduces the number of man hours required to build and deliver a marine diesel engine, which would otherwise be shipped by rail or truck. On a low-speed engine alone, the waterfront facility will save thousands of man hours," in turn providing cost and schedule benefits to customers. For medium-speed diesel engines and gas turbine applications, Westinghouse will supply reduction gears, shafting and controllable pitch propellers. Westinghouse has an 80-year history in marine reduction gear manufacturing. The company has off-the-shelf designs for double-input medium-speed diesel reduction gears and a single input LM2500 gas turbine reduction gear; more than 125 Westinghouse reduction gears for LM2500's are in controllable pitch propellers such as this Escher service or have been delivered.

To complete the package, Westinghouse announced in February an agreement with Sulzer Escher Wyss for Westinghouse to market and manufacture large, high-horsepower controllable pitch propellers in the U.S. for Sealift and other Navy ships. Sulzer Escher Wyss is a leading designer of controllable pitch propellers, with more than 1,800 Escher Wyss propellers in service worldwide, including a 46,000 horsepower controllable pitch propeller.

Westinghouse/Escher Wyss controllable pitch propellers will be capable of propelling ships up to 50,000 hp per propeller shaft.

For more information on Westinghouse marine products and services.