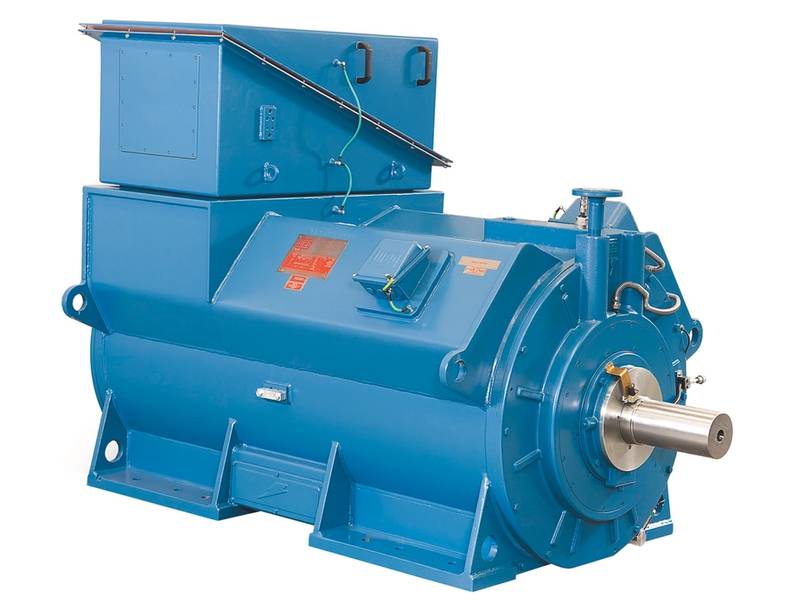

Water-cooled WGM Motors From WEG

WEG, a supplier of drive technology, introduced its water-cooled WGM motors to the shipbuilding industry for the first time at SMM 2014.

The WGM water-cooled induction motors are compact, offer low noise emissions, provide optimal heat dissipation and are suitable for frequency inverter operation. As such, they are suitable for a wide variety of applications on ships or offshore platforms including drive systems for main or maneuvering propulsion, and for pumps or fans.

WGM motors are cooled by a water jacket consisting of tubes or a cavity filled with water. An external water supply provides a constant, uniform flow of water between the stator core and the housing, ensuring effective cooling of the housing and end shields at all times. The water jacket removes waste heat from the motor more efficiently than air cooling, therefore enabling higher power density and smaller motor dimensions. With output power ratings up to 3,150 kW and frame sizes from IEC 315 to IEC 560, the WGM motor series covers the voltage range from 690 V to 6,600 V.

Noise emissions are also reduced considerably by the water jacket. The extremely effective cooling and high protection rating (IP55 as standard, with IP56 and IP65 available as options) ensure reliable motor operation, even under aggressive ambient conditions.

WGM motors have good overload characteristics, maintaining their rated torque all the way to the base frequency, so they can also be operated from a frequency inverter at zero rpm. This makes WGM motors an ideal choice for many tasks in the marine and offshore sector such as applications with frequency inverter operation that require constant torque in the low-speed range. For example, they can be used to operate the rudder drives of ships in dynamic position (DP) control for extended periods at very low speed.

WGM motors have two to eight poles, grey cast iron housings and can be operated at frequencies of 50 or 60 Hz. They are water cooled in accordance with IC71W and conform to insulation class F or H. The motors can also be equipped with flowmeters and leak detectors, among other accessories. For marine applications they can be supplied with ship certifications from ABS, Lloyd's Register, DNV and BV.

Related News