Damen Repeats Multiple Vessel Transport Strategy

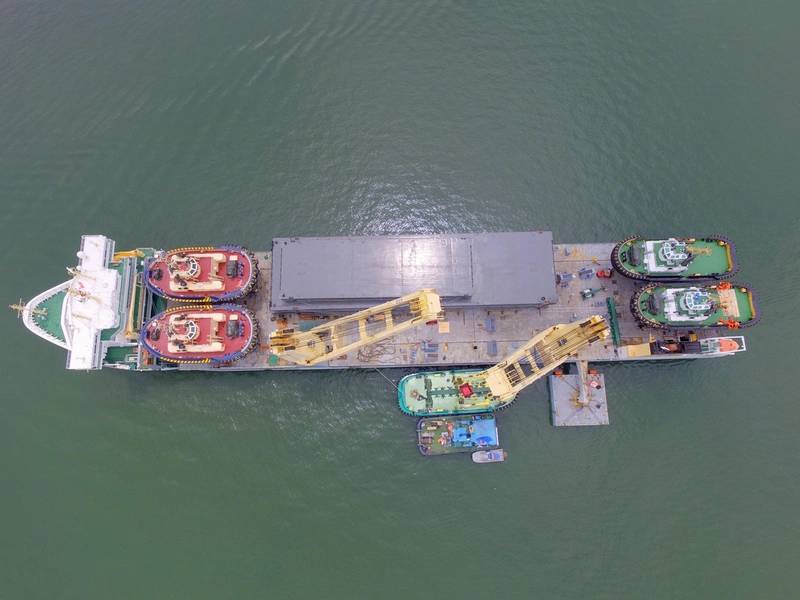

Just down river from Damen Song Cam Shipyard, SAL Heavy Lift’s MV Svenja departed from Halong Bay loaded with 14 vessels. The shipment consists primarily of built-for-stock vessels – Stan Pontoons and Tugs – which will be available for immediate purchase on arrival in Rotterdam in October.

Destination Rotterdam

MV Svenja’s voyage began in Shanghai on August 30th when she started loading eight Stan Pontoons that were built at Damen Yichang Shipyard, China. This first load includes Stan Pontoons 4113, 4111, 4512, 5211 and 6316.

MV Svenja’s voyage began in Shanghai on August 30th when she started loading eight Stan Pontoons that were built at Damen Yichang Shipyard, China. This first load includes Stan Pontoons 4113, 4111, 4512, 5211 and 6316.

The 12,975 DWT SAL Heavy Lift vessel then sailed to Ha Long Bay in Vietnam to pick up six tugs that were built at Damen Song Cam Shipyard.

The sailing itinerary involves sailing around the Cape of Good Hope instead of the shorter Suez Canal route. Despite this longer route towards Europe, MV Svenja’s ability to steam at an average of 18.5 to 19 knots will result in a shorter overall transit time; a significant factor in meeting Damen’s delivery schedules. The final destination is Rotterdam, the Netherlands, with arrival expected 15 October.

Striving for efficiency

“Transporting multiple vessels on one heavy-lift ship makes the whole delivery process as efficient as possible,” informs Damen Service Coordinator Heavy Lift Rimmert Berlijn. “This, in turn, allows us to keep our prices as low and as competitive as possible.”

“Transporting multiple vessels on one heavy-lift ship makes the whole delivery process as efficient as possible,” informs Damen Service Coordinator Heavy Lift Rimmert Berlijn. “This, in turn, allows us to keep our prices as low and as competitive as possible.”

While the success of this strategy is proven – last year, for example, 38 vessels were transported in two separate transports – Damen is a company that is renowned for its efforts to improve its already proficient operations. “We are continually looking for better options: ways to make things even more efficient.”

Smooth planning

Such a vessel transport requires precision planning. Most notably, in terms of building vessels for stock, Damen sales teams and product groups carefully analyse a wide range of customer and market requirements. Consequently, the company is in a position to offer ship owners swift deliveries of competitively priced vessels.

Such a vessel transport requires precision planning. Most notably, in terms of building vessels for stock, Damen sales teams and product groups carefully analyse a wide range of customer and market requirements. Consequently, the company is in a position to offer ship owners swift deliveries of competitively priced vessels.

It is also crucial that the logistics of such a transport is accurately planned. “On this subject, we are happy to work once again with SAL Heavy Lift,” continues Mr Berlijn. “Their technical abilities and seamanship skills are essential when it comes to designing and executing optimal stowage and lashing solutions for such a voyage. What’s more, they are experienced with our standards and our products. The cooperation that we have is always smooth and pleasant.”

SAL Heavy Lift will divide the Stan Pontoon loading between the MV Svenja’s 107.10×17.00×13.70-meter cargo hold and 128.50×27.50-meter main deck. All six tugs will be loaded on the main deck.