Reducing Complexity in Marine Winches with Powertrain Solutions

The Challenge

An international engineering technology company that strives to develop unique, innovative, sustainable products for their customers needed assistance with designing a marine winch, which is a critical component in the marine industry. This component is used for the control, lifting, and retrieval of remote operated vehicles (ROVs) on sea/ocean fairing vessels.

The winch needed to lift a type of ROV called a hull cleaner, which is designed to remove fouling on the ship hull. This reduces the risk of transporting biological contamination across different zones, and improves fuel efficiency on the ship.

The company discovered they could not find a winch solution that met all their objectives on their own. They had an initial concept in mind but wanted help reducing its complexity and potential maintenance. By partnering with the Powertrain Solutions team at Regal Rexnord, they were able to eliminate components from their original concept, while meeting the tough demands of a seafaring application.

The Solution

There were both physical and functional challenges to keep in mind when designing the marine winch. The physical needs of the winch were high corrosion resistance in the harsh salt spray environment, a simplified design to minimize potential failures and maintenance, and ensuring it was small enough to fit the limited enclosure size on the vessel. Functionally, the winch needed to meet the torque and speed requirements to have enough torque development to control, retrieve, and lift the ROVs, while also having dynamic braking to both let out more line for the ROVs and hold the brake to lock the line.

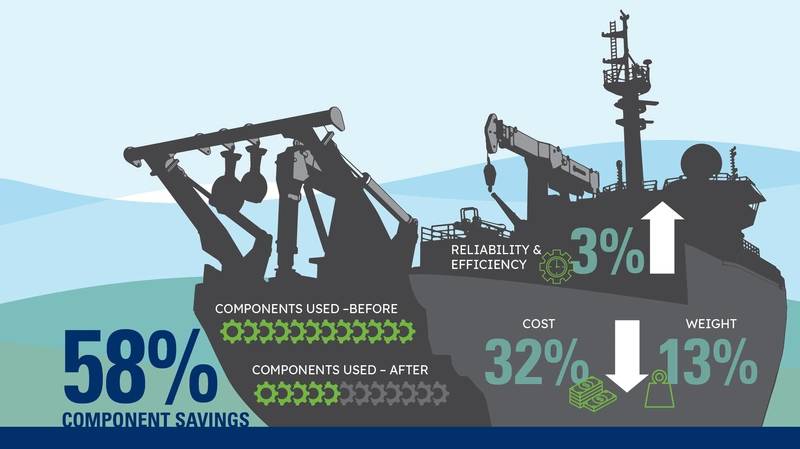

The Powertrain Solutions team partnered with the engineering technology company to come up with a design that significantly reduced the complexity, cost, and weight of their original concept, while increasing its robustness. The complexity was reduced by 58% by eliminating seven components, such as the synchronous belt, sheaves, belt guard, and flange mounted bearing, and by combining the motor, brake, and encoder into one Kollmorgen servo motor.

The Results

In addition to reducing complexity, these changes reduced the cost of the entire winch system by 32% and its weight by 13%. Reliability and efficiency also improved by 3% and maintenance was reduced by removing the synchronous belt and sheaves, as they have a hard time standing up to the exposed saltwater environment. The Kollmorgen servo motor and drive with resistive load bank allows the customer to dynamically brake by dumping power to the resistor bank and hold statically via an integrated holding brake inside the motor. Multiplying the motor braking through the gearbox ratio allowed a much smaller braking solution than the initial drum winder shaft-mounted brake that the customer used, resulting in a significant cost reduction.

Finally, the customer was able to eliminate one of the roller bearings and bearing mounts that support the drum winder shaft by rigidly mounting the gearbox and using the gearbox’s overhung load capability to support the drum winder instead.

While the individual components in the proposed design have a higher upfront cost, having fewer of them results in an overall lower total cost solution. Additional benefits of the Powertrain Solutions winch assembly include:

- Simplified assembly with fewer components resulting in a 50% reduction in time.

- Reduced processing costs, fewer logistics hassles, and one partner for the entire system by using a single supplier.

- Faster response time (acceleration & braking) and redundant braking (motor dynamic braking and

servo motor brake) with the improved design. - Improved safety (load dropping if the belt fails) and reduced guarding required (lower cost) due to the elimination of the belt system.

This collaboration exemplifies how innovative engineering can simplify complex systems, reduce costs, and enhance performance. By rethinking the original winch design, the company achieved significant reductions in complexity, weight, and maintenance, while improving reliability and efficiency. This streamlined approach not only met the rigorous demands of a marine environment but also delivered a robust and cost-effective solution that exceeded the customer’s expectations.