NAPA, ClassNK Team on New Data Link to Support 3D Ship Design

Upgraded data linkage designed to enable the seamless flow of information between design and class approval software, reducing time spent on information transfer by 30% and fostering closer collaboration.

NAPA and ClassNK recently fortified their partnership to support the use of 3D models in the ship design approval process by streamlining data sharing between design and class approval software.

“As the capabilities of 3D computer-aided design software improve, we see an acceleration in the use of 3D technologies in the shipbuilding industry," said Dr. Toshiro Arima, Corporate Officer, Director of Rule Development and ICT Division at ClassNK. "At ClassNK, we are dedicated to supporting this transition with a powerful software environment that puts 3D models at the forefront to facilitate approval and collaboration between all partners. Today’s announcement builds on previous collaboration with partners on a study to facilitate the class approval process using 3D models, and we are proud to be at the forefront of innovation on this vital issue.”

According the organizations, it saves time and allows designers, engineers, and class societies to collaborate more effectively on vessel designs by using a consistent 3D model throughout.

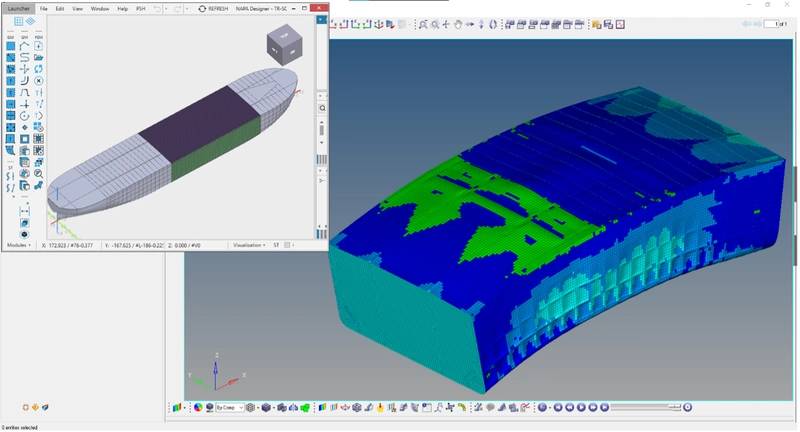

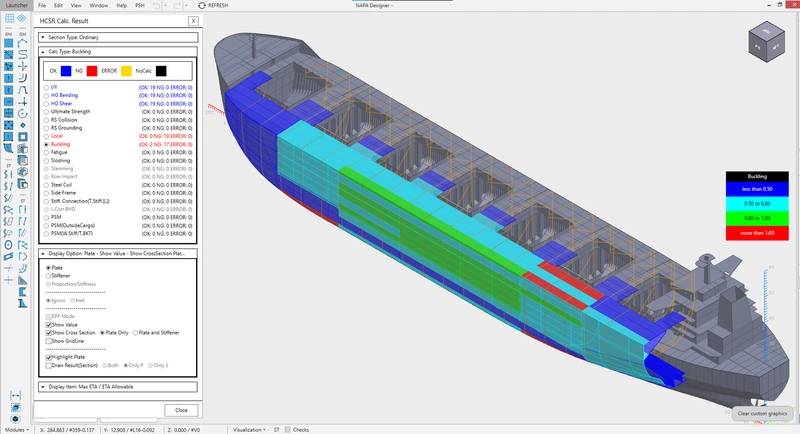

The partnership will enhance data sharing between NAPA’s 3D Computer-aided design (CAD) software NAPA Designer and ClassNK’s design support software PrimeShip-HULL. The two systems will now be directly linked through NAPA’s Application Programming Interface (API) rather than relying on intermediate files.

According to the orgamizations, the streamlined system will reduce the person-hours required for data linkage by more than 30% compared to the current method while also improving the accuracy of linkage and limiting the risk of errors.

This latest upgrade will also enable closer collaboration between designers and class societies. It allows users of the PrimeShip-HULL system to carry out direct strength and prescriptive calculations on NAPA Designer seamlessly. Moreover, any amendment to dimensions following these calculations will be directly reflected in NAPA Designer’s 3D models. The new function is currently available for bulk carriers and oil tankers, applying the Common Structural Rules for Bulk Carriers and Oil Tankers (CSR BC & OT) requirements.

“The use of 3D models throughout the design process of a ship, including for the class approval process, is an integral part of the future of naval architecture," said Tapio Hulkkonen, Director, Product Management, Design Solutions, NAPA. "At NAPA, we are proud to drive this vital transition forward by developing solutions that enable all stakeholders to collaborate on the same 3D model, instead of wasting time and resources on multiple conversions to 2D drawings. This makes the design process more efficient, saves time and money, and reduces the risk of errors."