3D Printing News

IACS Publishes New Recommendation on 3D Printing

The International Association of Classification Societies (IACS) has published a new recommendation, Rec.186, that meets the need for a standardized approach to integrating additive manufacturing (AM), commonly referred to as 3D printing, into marine and offshore applications.The maritime industry continues to embrace developments in manufacturing technologies to enhance efficiency and sustainability in shipbuilding and offshore operations. Additive Manufacturing (AM) has emerged…

3D Printed Valve Manifold Assembly Installed on US Aircraft Carrier

HII has announced that shipbuilders at its Newport News Shipbuilding (NNS) division have successfully installed the first valve manifold assembly created by 3D Printing (additive manufacturing) on a new construction aircraft carrier.The valve manifold assembly, a specialized assembly that allows distribution of a single source of fluid to multiple points on the ship, is installed in a pump room on Gerald R. Ford-class aircraft carrier Enterprise (CVN 80). The assembly, which is approximately 5 feet long and 1…

Austal USA Buys WarpSPEE3D Printer

Austal USA Advanced Technologies (Austal USA AT) has purchased a WarpSPEE3D printer and is currently spearheading an effort to revolutionize the US Navy's supply chain by implementing additive manufacturing.Austal USA AT oversees and operates the Navy's Additive Manufacturing Center of Excellence in Danville, VA – the US Navy's flagship center for additive manufacturing supporting the construction and sustainment of the fleet. SPEE3D's proprietary Cold Spray Additive Manufacturing…

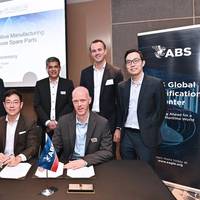

ABS and HD Hyundai Heavy Industries Sign JDP to Advance 3D Printing

ABS and representatives from an HD Hyundai Heavy Industries (HHI) consortium signed a joint development agreement (JDP) that paves the way for the onboard manufacture of repair parts.Using a digital library for the design process and 3D printing, also known as additive manufacturing (AM), the consortium aims to support rapid maintenance, repair and operations (MRO) on sailing merchant vessels focused on metallic materials. Project partners include ABS; HHI; CScam, 3D printer manufacturer…

3D Printed Spare Part Cuts Downtime for Wallenius Wilhelmsen's RoRo Vessel

Pelagus 3D said Wednesday it had delivered a Return Oil Standpipe at Kobe, Japan, to be installed on Wallenius Wilhelmsen's RoRo vessel TYSLA. The collaboration involved Kawasaki Heavy Industries and Wilhelmsen Ship Management.Traditionally, the procurement, fabrication, and delivery of specific spare parts has been a time-consuming process, often leading to costly downtime for the maritime and offshore industries. However, with the advent of Additive Manufacturing (AM), also known as 3D Printing…

ABS and Pelagus 3D to Advance Additive Manufacturing for Spare Parts

ABS and Pelagus 3D Pte. Ltd., a joint venture company of thyssenkrupp and Wilhelmsen, signed a memorandum of understanding (MOU) to advance the technologies and adoption of on-demand additive manufacturing (AM) of marine and offshore spare parts.During a three-year term, ABS and Pelagus 3D will collaborate on a variety of initiatives including the incorporation of ABS testing requirements through the Pelagus Platform for AM parts. This project will also support the continued development of industry guidelines and standards for AM…

ABS Joins Korean Partners on 3D Printing Project

ABS signed a memorandum of understanding to work with key stakeholders in Korea to develop and demonstrate a 3D printing system for ocean-going vessels.Using a digital library for the design process, the system aims to support rapid maintenance, repair and operations by using 3D printing, also known as additive manufacturing (AM), to manufacture parts on a vessel while at sea.ABS joins project partners Ulsan Metropolitan City, Ulsan ICT Promotion Agency, Korea Institute of Industrial Technology…

Thyssenkrupp, Wilhelmsen Create 3D Printing Firm of Maritime & Offshore Sectors

Wilhelmsen and Thyssenkrupp announced on September 29 their joint venture company, Pelagus 3D, marking the entry of a new player into global maritime and offshore services market."Pelagus 3D envisions to be the largest one-stop, on-demand digital manufacturing partner for the maritime and offshore industries. It uses Additive Manufacturing (AM) or 3D printing to deliver maritime spare parts more efficiently in terms of time and cost, allowing customers to ensure their vessels’ seaworthiness and keep their operations moving on schedule…

3D Printing: Navy Builds Up Additive Manufacturing on Ships

The U.S. Navy has long valued the potential of additive manufacturing (AM) and 3D Printing.AM refers to the depositing of material layer by layer to create an object. For the Navy, it’s not practical to carry every replacement part for every system on a ship, and it can be difficult to forecast if or when parts will fail. AM provides a flexible source of supply in being able to make parts instead of ordering them and waiting for them to arrive, especially for warships at the far end of the supply chain.

Presentation of "The 3-D Printed Vessel" at WFSA event

Vessels fashioned in a 3D printer, rather than a shipyard, will be the subject of a presentation at a Worldwide Ferry Safety Association (WFSA) event. The virtual gathering, Innovations in Ferry Design and Vessel Construction, will be held in conjunction with the presentation of awards inWFSA’s Annual Student Design Competition, now in its ninth year, to be held on May 18, 2022.The keynote speaker, Dr. Habib Dagher, from the University of Maine, Advanced Structures and Composites Sector, will talk about the Center’s design and construction of the world’s largest 3D printed vessels.

DNV Awards Type Approval for 3D Printing Feedstock

Voestalpine Böhler Welding Germany GmbH has become the first manufacturer worldwide to be awarded a Type Approval certificate from classification society DNV, for their solid wire 3Dprint AM 70/I1 feedstock. The Type Approval has been awarded based on DNV’s new class programme, DNV-CP-291 “Additive Manufacturing Feedstock”.The Type Approval certificate was presented to voestalpine Böhler Welding Germany GmbH during the DVS Congress held in Essen, Germany, and is the first of its kind to be issued by a classification society.

ABS Approves 3D Printed Spare Parts After Tanker Trial

Parts fabricated by additive manufacturing (AM) – also known as 3D printing – and installed on an oil tanker for operational testing have been validated to be in good working condition, marking a significant step for the technology's implementation in the marine industry.The project involving ABS, ConocoPhillips Polar Tankers, Sembcorp Marine Ltd and 3D Metalforge started in February 2021 with the fabrication and lab-testing of functional additive manufactured parts, which were then installed on board the oil tanker Polar Endeavour.

Huisman Scales Up 3D Printing

Cranes manufacturer Huisman said it has successfully tested four new 3D printed 350mt crane hooks under the supervision of the independent certification authority Lloyd's Register.The hooks are approx. 170 by 130cm in size, almost nine times larger than the first Huisman 3D printed crane hook, the company said. They have a weight of 1,700kg each and a loading capacity of 350mt. Each hook exists of approx. 90 kilometers of welding wire.Huisman has been employing the 3D printing…

Tech File: Naval Postgraduate School Adds Xerox ElemX 3D Printer

The Navy is a step closer to achieving the vision of being able to fabricate parts on demand. Xerox and the Naval Postgraduate School (NPS) have announced a strategic research collaboration to advance 3D printing and additive manufacturing.As part of a Collaborative Research and Development Agreement (CRADA) between NPS and Xerox, a Xerox ElemX Liquid Metal Printer has been installed at the school’s Large Experiment Annex on campus. NPS is the first site anywhere in the world to install this new technology.“From the age of sail to the nuclear era…

Naval Postgraduate School adds Xerox ElemX 3D Printer

The Navy is a step closer to achieving the vision of being able to fabricate parts on demand. Xerox and the Naval Postgraduate School (NPS) have announced a strategic research collaboration to advance 3D printing and additive manufacturing.As part of a Collaborative Research and Development Agreement (CRADA) between NPS and Xerox, a Xerox ElemX Liquid Metal Printer has been installed at the school’s Large Experiment Annex on campus. NPS is the first site anywhere in the world to install this new technology.“From the age of sail to the nuclear era…

Tech File: 3D Printed Prop for French Warship

Naval Group manufactured a new-generation propeller via a metal 3D printing process, mounted on a tripartite minehunter.This propeller is 2.5-m in diameter, supported by five 200-kg blades. The equipment left the workshops of the Naval Group site of Nantes-Indret in October 2020 for the site of Brest in order to be mounted on the ship's propeller shaft. As part of its major technical stop, the assembly was transferred to the submarine base to be mounted on the intermediate shaft of the Andromède in November.

TMS to Use 3D Printers for Submarines

German industrial conglomerate Thyssenkrupp Marine Systems (TMS) plans to use 3D printers increasingly in manufacturing submarine parts. This offers decisive advantages over conventionally produced components.The corresponding quality and safety approvals have already been granted. Through acquisition of the thyssenkrupp TechCenter Additive Manufacturing (in Mülheim an der Ruhr, North Rhein-Westphalia), the required technology and expertise will now come to the Kiel Fjord. It is planned to complete the transition by June 2020.Dr. Luis Alejandro Orellano, COO of thyssenkrupp Marine Systems said: "3D printing opens up completely new potentials for us. In the design engineering, we no longer have to consider the limits of conventional manufacturing processes everywhere.

Wilhelmsen Delivers 3D Printed Parts to Berge Bulk

Norway-based global maritime industry group Wilh. Wilhelmsen Holding ASA announced that Berge Mafadi, a Berge Bulk vessel has received the world’s first commercial delivery of 3d printed scupper plugs, as part of Wilhelmsen’s Early Adopter Program.According to a press release, the program, where customers have exclusive access to on-demand additive manufacturing was launched by Wilhelmsen’s Marine Products division in December 2019. Customers include Berge Bulk, Carnival Maritime, Thome Ship Management, OSM Maritime Group, Executive Ship Management and Wilhelmsen Ship Management.“We are very excited with this milestone - completing one of the first commercial deliveries of 3D printed parts in the maritime industry…

3D Printing for Offshore Wind Turbines Introduced

IT service provider Accucode is partnering up with RCAM Technologies, a specialist in large-scale concrete additive manufacturing, to develop large-scale, 3D printed concrete structures supporting offshore wind turbines.The partnership with Accucode comes on the heels of a grant announcement. RCAM Technologies recently received $250,000 from the Colorado Office of Economic Development and International Trade (COEDIT) through its Advanced Industries Accelerator Grant Program.The grant was awarded to RCAM Technologies for developing a 3D concrete printed wind turbine foundation that will reduce offshore deployment costs by up to $4M per foundation and $400M per wind plant.RCAM said it will use the funding to expand its 3D concrete printing capabilities at two partner locations: the U.S.

World First: Patrol Vessels Deploy 3D Printers

3D printing technology developed in Darwin will be deployed by the Royal Australian Navy in a world-first trial that will streamline the maintenance of patrol vessels.The Morrison Government will invest $1.5 million in the two-year Supersonic Deposition 3D printer pilot, which will lead to a significant increase of parts availability compared to what the regular supply chain can provide.Minister for Defense Industry, the Hon Melissa Price MP, congratulated the Charles Darwin University’s Advanced Manufacturing Alliance, along with industry partner SPEE3D, for producing the cutting edge and uniquely Australian capability.“This high-tech machinery enables metal components to be produced quickly and efficiently…

PGS Releases 3D GeoStreamer Survey Data

Norwegian seismic services provider Petroleum Geo-Services (PGS) said that beam migrated data is now available for viewing on its latest 3D GeoStreamer seismic survey over Angola blocks for the 2021 bid round.Modern imaging will unlock links between onshore and offshore presalt and postsalt plays.“Our initial coverage of shallow blocks six to eight will allow interested E&P companies a head start on de-risking prospectivity of the area ahead of bid submissions in 2021”, says Christine Roche, New Ventures Manager for PGS in Angola.Commercial, strategic and technical benefits are available to early participants in the survey. Preferential…

DNV GL Application for 3D Models in Offshore

With the release of DNV GL’s Sesam Insight application, which provides shared 3D models among all stakeholders, costly barriers in offshore engineering are removed.When analysis models and data are stored in several places, there is a risk of costly and time-consuming information exchange between the involved players, such as owners, operators, contractors and regulatory bodies. This lack of transparency can lead to issues during the verification process, and uncertainty about the status and quality of project work.In some cases, knowledge and data remain with contractors instead of asset owners, and data recovery costs can be high.With the release of the Sesam Insight solution from DNV GL…

Thyssenkrupp Wins 3D Printing Approval

The international accredited registrar and classification society DNV GL has awarded thyssenkrupp, German multinational conglomerate, first additive manufacturing approval of manufacturer certificateThe shipping industry is looking to take advantage of additive manufacturing (AM), also known as 3D printing, to print spare parts, thereby reducing lead times, costs, stock requirements, and environmental impacts. Certification ensures that AM part users can have the same confidence in an additive manufactured product as a conventionally produced one.The newly issued certificate makes the thyssenkrupp TechCenter Additive Manufacturing the world’s first producer of 3D printed parts for maritime applications to obtain manufacturer approval from DNV GL.