Marine Propulsion: Inside Schottel's New SRP-D

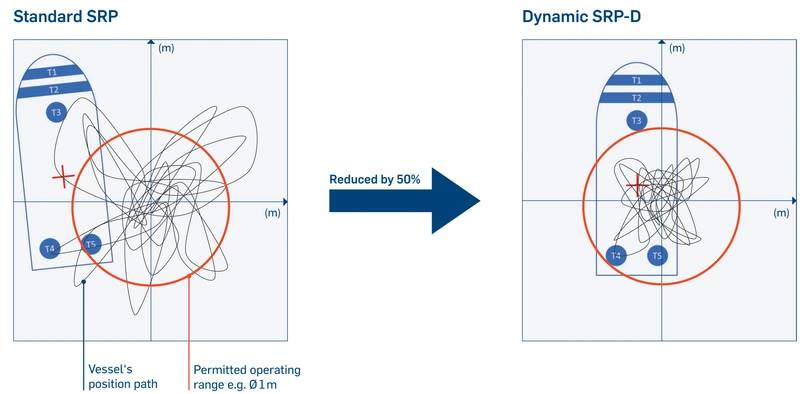

The increased performance of the fast-responsive Schottel RudderPropeller Dynamic SRP-D was confirmed by external sources. Initial investigations into the effect of thruster response on DP positioning were carried out in cooperation with MARIN, based in the Netherlands, and Polish ship designer MMC. The results obtained demonstrated much-improved position accuracy and enhanced operability of the vessel.

Further calculations made by DNV and simulations from a cooperation with VARD showed that the SRP-D greatly improves the vessel’s operational performance and environmental impact, showing too that the DP footprint can be significantly reduced, coupled with expected fuel savings of up to 30 percent depending on the operating point.

“The results presented in MARIN’s dynamic DP simulations indicated a significant benefit as regards the operability of the vessel," said Michał Olko, Vice-President and Chief Designer, MMC Ship Design. "We’re convinced that this fast responsive thruster will be the preferred choice for SOVs, allowing them to meet operational requirements in terms of DP accuracy and overall performance.”

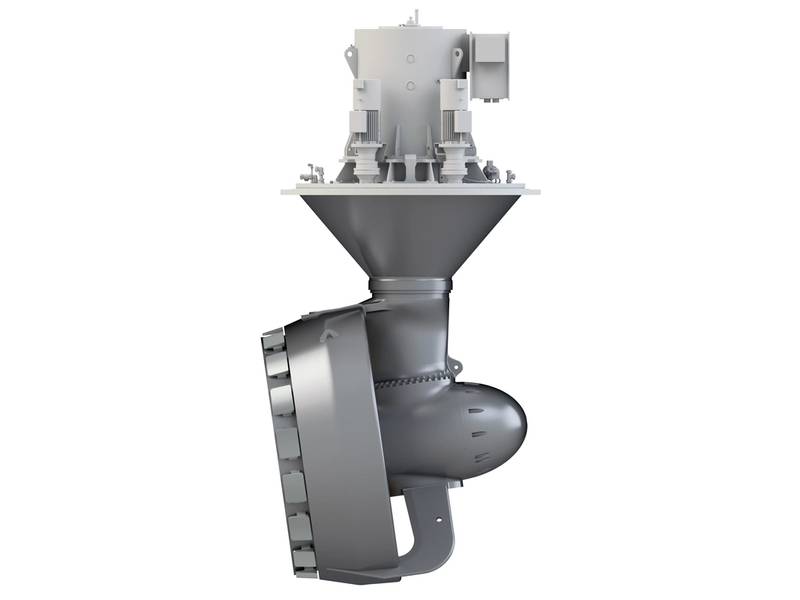

In addition to the embedded electric main drive (LE-Drive) and a propeller shaft with an eight-degree tilt, the SRP-D features a number of improvements, including reduced propeller acceleration/deceleration times and a high-speed azimuth steering system with reinforced gear components, thus achieving double the rotational speed. The dynamic properties of the SRP were investigated within a time domain level three analysis commissioned by DNV.

The simulation was performed on the numerical model of a real Service Operation Vessel (SOV) equipped with Schottel propulsion systems. Its position-holding capabilities were examined under extreme weather conditions: high winds, strong currents and effective wave heights of 2.5m and 3.2m. The results of the simulations at DNV showed a significantly improved positioning accuracy while halving the DP footprint. This permits successful gangway landing operations even in rougher conditions, thus increasing the service life of the vessel throughout the year. Furthermore, every single landing is performed more efficiently, saving time and fuel.

Efficiency Gains

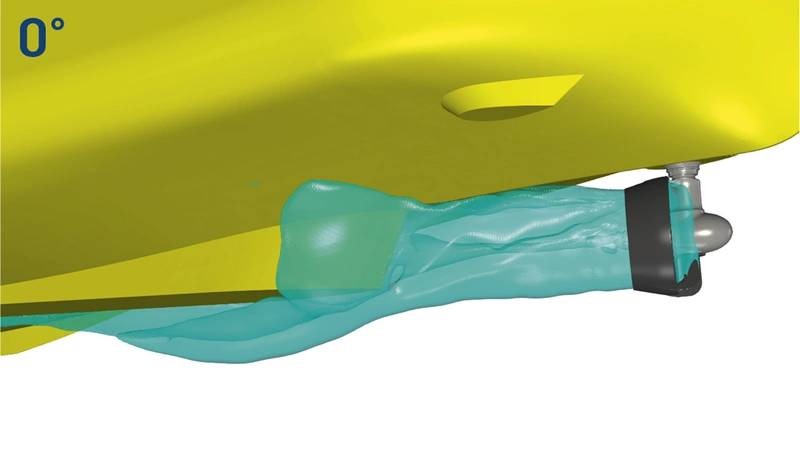

Thanks to the lower gearbox that has an additional eight degrees downward tilt, the interaction between propulsion unit and hull and the propeller flow interaction are reduced. As established in the simulations, these optimizations result in an increased thrust efficiency during DP. Depending on the thruster’s operational direction, simulation also revealed up to 50 percent less thrust loss and fewer forbidden zones.

“The CFD results of the inclined gear box clearly show a significantly reduced thruster hull interaction or Coandă effect for zero-speed station-keeping," said Karl Randle, Principle Naval Architect, VARD. "This is especially evident for inward flow directions and areas where the flow interacts with or flushes the skeg or other thrusters. The benefits of reduced thrust deduction could be significant for designers and owners in many applications when such considerations are included in detailed analysis procedures.”

The implemented optimizations yield additional savings in fuel consumption, too. Thanks to the faster response time of the propulsion, the vessel can be quickly held in position with only minor corrections being necessary. This prevents major corrections in position having to be made which would require more power. Depending on the operating point and environmental conditions, this can save up to 30 percent in fuel during DP operation compared to standard rudder propellers.