Eye on Design: Hybrid Blood, Sweat, and Tears

In earlier columns, I have discussed various approaches and issues with Hybrid Propulsion.

I have now had the pleasure of a number of years of experience with the design, operation, upgrade, modification, and maintenance of ship (and car) hybrid propulsion systems and may be able to make a claim of gradually becoming a little less confused.

It is still not easy, but at the same time, I am starting to see a few shortcuts that make it less likely that a beautiful vision of marine efficiency ends up being beached somewhere.

In essence, they are variants of the KISS (Keep It Simple Stupid) principle. KISS in marine design was never easy, but when KISS needs to be integrated with sustainable design it become even more complicated.

In particular I have become very cagey of IC/battery electric hybrid systems. These are the systems that are basically diesel-driven, but use a battery setup in the same way that the original Toyota Prius used a battery for boost. In running the numbers in certain applications (like docking tugs), it becomes apparent that this can result in decent CO2 emission reductions.

A number of such systems have been installed, and some work. However, when they don’t work for any one reason, these systems are very difficult to fix because they tend to be heavily integrated systems. If any one component acts up, the whole system shuts down. Ashore, that means the car gets taken to a dealer, spare parts are sourced, installed in a dedicated facility, and the car is put back on the road.

In maritime, that does not work out so easily. There can be any number of obstacles in getting the vessel back onto the water. The parts may not be readily available. The service technicians may not be readily available. There may be auxiliary system bugs or spikes that result in intermittent failures, and most frustrating of all, the OEM may tell the ship owner that they no longer support the equipment/software, or repair technicians.

In the worst possible case, the Owner is looking at a pile of components with very little prospect of getting the vessel to run again. In the best possible case, the vessel can run as a conventional (inefficient) diesel powered vessel if the engines are geared to the shafts, possibly for the rest of its life.

It appears to me that ship hybrid system designers have tried to give the ship’s crew the same experience as a hybrid car owner; somewhat reduced emissions by fitting more magical stuff. However, a ship’s crew is not a hybrid car owner. A ship’s crew is actively engaged in the planning of the use of its available and required power. A car operator does not ponder whether they need to run one or two auxiliary generators, but a ship operator does.

A marine hybrid system should not make decisions for the operator; it should allow the operator to make decisions. Therefore, a system that automatically brings in battery boost is not of great use. A ship operator will know when she needs boost, and can then look at her batteries to see how much boost is available and decide to bring it online.

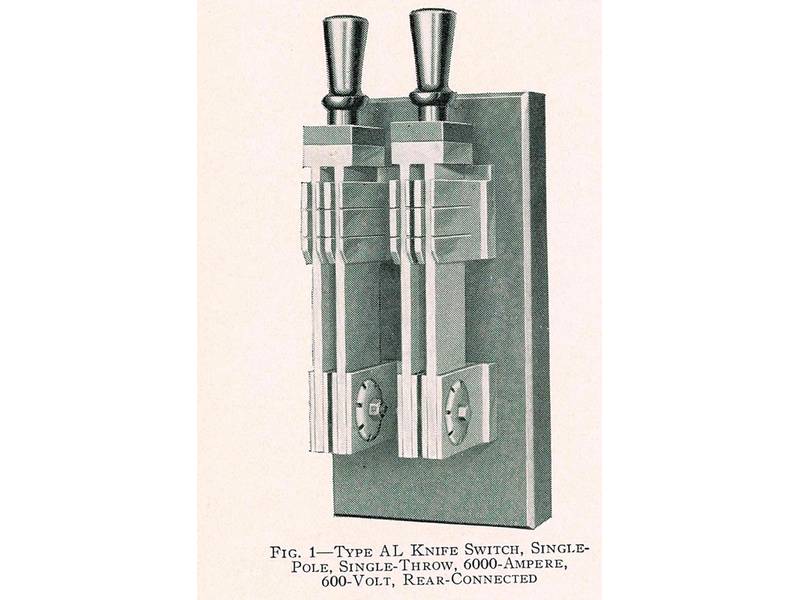

So, instead of sophisticated software and controllers, we need to think in terms of the modern equivalent of big knife edge switches that can engage and disengage power suppliers as needed by the crew.

Don’t for a second think the crew is not smart enough to do that. This is what crews do; they anticipate their needs, whether it is food, sleep, maintenance. or power. And if your crew does not do that, it is probably time to get another crew, because your ship has become an accident waiting to happen.

So, what does KISS mandate then for hybrid systems?

From my side of the problem (vessel designer and operator), it looks like we need to design for CO2 reduction, redundancy, and economic upgrades.

As far as I have been able to figure, that can only be achieved one way, and that is by electric drive. Every new vessel needs to be built with electric motors driving the shafts that can take electric power from any one, or a combination of electric power generators. (And should be as isolated as possible from the auxiliary electric bus to prevent voltage spikes and other gremlins.)

The actual propulsion controls (the throttles) are integrated into the electric drive system, but the electric power producers are only very lightly integrated into the propulsion controls, and the operator can manually select whatever power input it has available. If there is battery capacity and the trip is short, she may choose to just run on batteries. If it is a long run and another power supplier is a methanol fueled generator, she may choose to bring that unit online when needed. If they can be designed to run simultaneously, that is fine, but it should always be possible to move a big knife switch and force the system to work on just batteries or just the methanol-fueled generator. That seems clunky, but this is the feature that allows ship operators to make decisions about getting home, rather than getting stuck with complex troubleshooting somewhere far away from help with a system that has decided to shut down.

When the vessel propulsion core is electric drive, the possibilities to achieve zero carbon become available as technology advances, and that can be more economically achieved than with complex hybrid system upgrades.

Initially (but hopefully not), the vessel may be diesel electric drive. That is not a great solution, but it would not be economically prohibitive at some stage to toss the diesel and go to batteries, or to add batteries and use the diesel less, or to convert the diesel to methanol. In other words, the system should be designed for progressive upgrades and avoid any controls that may become obsolete or may suffer from programming bugs, voltage spike gremlins, or loss of OEM support.

Since hybrid systems tend to be designed for specific trades, what is even more fun is that the “electric drive first” approach allows more economical modifications of a vessel when it changes trades. For example, a ferry may originally be designed for a relatively large range with an LNG powered electrical generator, but partway into its economic life, it may become a candidate for a shorter or slower run, and with emerging battery technologies and shore charging, she may be an attractive candidate for a true zero carbon configuration of batteries alone. Since the vessel is inherently electric drive, the upgrade will be no more that battery installation and removal of the LNG IC system and that is a good thing, because scrapping useless vessels for new ones also emits CO2.

For each column I write, MREN has agreed to make a small donation to an organization of my choice. For this column I nominate the Virginia Maitland Sachs Foundation.This organization introduces young people to maritime careers as their path to the middle class, and complex but satisfying careers.