Electric Propulsion: The Dawn of a New Generation of Marine Power?

Technological advancement is opening new doors for hybrid and fully electric vessels.

In mid-2020, the U.S. Navy accepted the delivery of the USS Zumwalt, the Navy’s first full-electric power and propulsion surface combatant. The ship’s new electric propulsion plant provides favorable efficiency coupled with a reduced total cost of ownership. The design is flexible and efficient to deliver power where it’s needed, when it’s needed. Its adoption is symbolic of a maritime future and what could be in store for other marine craft, both inland and on the high seas.

Such technological advancement is encouraging at a time when the world’s maritime industry delivers greater than two-thirds of all global trade, but also are tagged as a notable contributor to adverse carbon emissions. Electric propulsion and its versatile power capabilities make it attractive environmentally and economically.

“We have been working to address the challenge of zero emissions for decades and see great promise for widespread adoption of the technology in the marine industry,” says Peter Brooks, account Manager for marine and port solutions, for the power and propulsion solutions business area within electronic systems at BAE Systems’ power and propulsion solutions based in Endicott, N.Y. BAE has helped develop several marine craft with electric propulsion.

Inland craft as early adopters

Bowers adds that an influx of electric propulsion is finding more inroads as a means of propulsion for inland craft. “In recent years, we’ve seen more vessel operators strive to adopt the technology and get closer to zero emissions. Most notably, we see passenger ferries at the forefront of adoption, but other market segments are starting to emerge such as inland towing with new construction and repowers,” he says. “There has also been a recent surge of interest in the tug and harbor craft market with operators wanting zero emissions capability in the port area.”

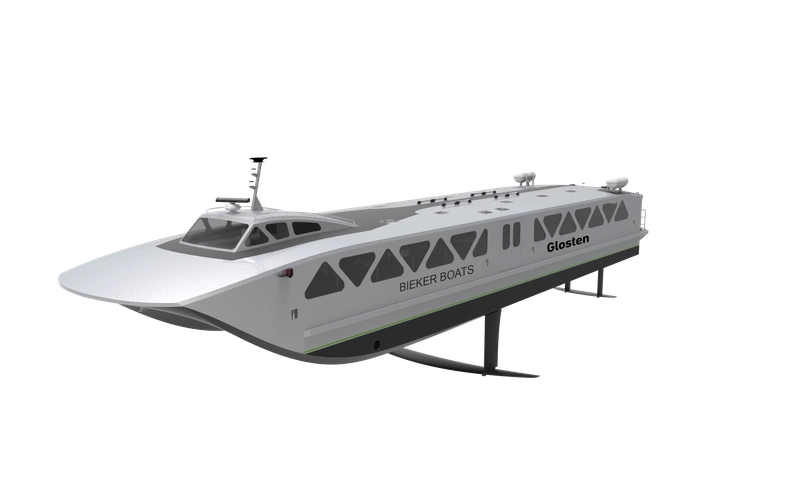

Jim Wolfe, PE is a senior electrical engineer with Glosten in Seattle. He also says that much of maritime industry within inland and point-to-point operations are where the hybrid and all-electric vessel emergence should enter “fastest and hardest.” “The defined routes and defined operations are much easier to plan and design around than vessels that require more flexibility in capabilities,” Wolfe says. “Short duration voyages are readily compatible with the current state of electrical energy storage technologies. The reduction in fuel costs and maintenance costs can offset the additional capital costs and training skills.”

Dave Lee is the senior accounts manager for ABB Marine and Ports’ Americas Inland River, Tug and Offshore sector. He believes that the inland craft market has blazed the trail for electric propulsion. They are the early adopters. But increasing standards of environmental compliance are drawing larger craft into electric propulsion.

“Operators are now faced with more expensive engines as well as higher operating cost with Tier 4 and current rates market day rates do not allow for any additional cost, may it be operational or capital,” Lee explains. “With this along with the current status of the market it has paused a lot of new construction; however, the pressure that operators are receiving from both regulatory bodies (EPA) as well as customers will pull them to adopt electric and hybrid technology. I would say early adopters are on the cusp of hybrid and electric towboats as they are faced with the issues we already discussed. As the early adopters prove to the industry that hybrid and electric is the way to go the industry will follow, much like almost every other marine industry has already proven around the world.”

Operational challenges

For further adoption of electric propulsion, vessel owners will face operational challenges. They will need to counterbalance such challenges with environmental and cost benefits as well as other benefits as well.

Joe Wolfel, CEO of Terradepth Inc. in Austin, Texas, says that any sustainable platform has operational challenges as they represent a new way of transporting goods. Alternative fuels and other means of propulsion beyond the traditional high, medium and slow speed diesel engines must consider the logistics of supporting new systems.

“There are challenges with the energy density of fuels that are safe to submerge, creating the need for larger platforms, which drives a cost increase,” Wolfel says. “Safe transportation, storage and handling are also challenges, as you combine volatile materials such as lithium, hydrogen or heavy fuels.”

For electric plants, there’s even a heavier burden of energy storage and an infrastructure to support any needed shore power connectivity or other interface while in port—domestically and abroad.

“We understand the challenges that boat builders face when adopting new technology and what it takes to make it certifiable for operation,” explains Peter Brook of BAE. “There are many factors when going electric, but the three key components to consider are power needs, types of technology and infrastructure. We closely examine power needs early in the design phase with the builder. No two vessels are alike, so our goal is to work with the customer to outline how much energy a vessel will consume when it is in operation. Some operators may not be ready to go all electric, so we believe it is important to offer incremental solutions that meet specific needs. Unlike electric cars, this is not a universal model, instead we believe that solutions should be tailored to a specific vessel. It is also important to note that you don’t need costly infrastructure or high grid power shore side to operate this technology on marine vessels. There are many vessels in operation today that use self-charging capabilities to recharge their batteries on board.”

Though larger vessels aren’t as concerned about battery charging for propulsion, they will likely need more battery storage and charging capacity for control systems that support them. In addition, electric propulsion is newer technology to operators and may require additional training and knowledge to operate and maintain main and auxiliary electric systems.

“System complexity and specialized skills are a significant barrier,” says Jim Wolfe of Glosten. “Large energy storage batteries and integrated hybrid systems require significant automatic controls to operate. Being able to effectively troubleshoot and maintain these systems requires a good understanding of the underlying software and hardware. This will be a barrier to some operations. Some system providers have highly integrated standard solutions that requires significant post-sale support and cannot be supported by third parties. This is a change for some operators who are used to managing maintenance internally or being able to select qualified contractors and could be a barrier for some public agencies.”

Bruce Strupp is ABB’s marine and ports senior account manager for the ferry sector. Strupp contends that while electric propulsion seems to favor inland and littoral operations, there’s still potential for the marine oceangoing sector as well.

“Operators tend to see more dramatic benefits in short distance shipping applications for zero emission and hybrid applications but there are still some benefits for deep sea and oceangoing vessels,” Strupp says. “We are seeing some oceangoing and deep-sea vessels install batteries to capture electricity that can be used in a multitude of different ways including zero emission port stays, a spinning power reserve, peak shaving, enhanced dynamic performance and strategic loading all of which can have a positive financial, safety and environmental impact for the operator. We are also seeing a lot of development of fuel cells for oceangoing and deep-sea applications and believe that there is significant potential for operator benefits.”

- Related: Interview: Joe Hudspeth, BAE Systems

Flexible power and beyond

The gist of the USS Zumwalt and the Littoral class vessels is to have power availability when you need it, where you need it. This is true for commercial operators as well and highlights a notable benefit of electric and hybrid electric propulsion.

“The greatest benefit is utilizing only the power you need at a particular time versus having all the equipment online and not needing the available power,” adds David Lee of ABB. “In other words, in a battery hybrid system you can utilize the batteries to not start a separate generator when there is a load demand for only a short period. In a traditional system you must have all the main engines on plus whatever number of generators all the time if you need the power or not. This correct utilization of power decrease both the cost of maintenance and the cost of fuel compared to the vessels of today.”

This flexibility will yield a host of benefit that goes beyond strictly vessel operation and attractive features for owners who may prosper from its flexibility. Beyond such flexibility though, is the use of a system that is cleaner, often quieter and more manageable for the crew than traditional diesels bringing fossil fuels. Then there’s also the environmental benefit atop all other. As with the USS Zumwalt, the overarching benefits of electric and hybrid electric power will unlatch new possibilities for marine propulsion and the environments in which they operate.

“Our vision is that this technology will not only help operators meet their emissions requirements but will create cleaner harbors and waterways in the places where we live, work and visit,” adds Peter Brooks of BAE. “The system itself allows for a very flexible install, giving naval architects greater freedom to maximize the use of vessel space. In addition to emissions reduction, operators benefit from reduced operating costs, while also improving passenger and crew comfort with quieter and smoother vessel operation.”