DSME Returns for More Dual-Fuel Engines

MAN Diesel & Turbo received an order for four MAN B&W 5G70ME-GI engines in connection with Daewoo Shipbuilding & Marine Engineering Co.,Ltd. (DSME) agreeing a deal with the BW Group to build two LNG carriers. The technical engine specification complies with IMO Tier II, with options to include remedies for Tier III compliance at a later stage. The 173,400 cu. m. vessels are scheduled for delivery in late 2017/early 2018 and will be built at DSME’s Okpo shipyard in Geoje, Korea. The deal represents the second LNG ME-GI contract for DSME after a previous order signed in 2012.

Compliance with IMO Tier III regulations requires an 80% reduction in NOx emissions– compared to Tier I– within the designated emission control areas (ECAs) over a defined test cycle. MAN Diesel & Turbo has developed two main approaches to comply with these challenges: Selective Catalytic Reduction (SCR), which involves the catalytically accelerated reaction of nitrogen oxides with ammonia to form water and nitrogen, and Exhaust Gas Recirculation (EGR), which works by re-circulating a portion of an engine’s exhaust gas back to the engine cylinders.

The ME-GI engine gives ship owners and operators fuel flexibility based on price and environmental considerations. MAN Diesel & Turbo sees significant opportunities arising for gas-fuelled tonnage as fuel prices rise and modern exhaust-emission limits tighten.

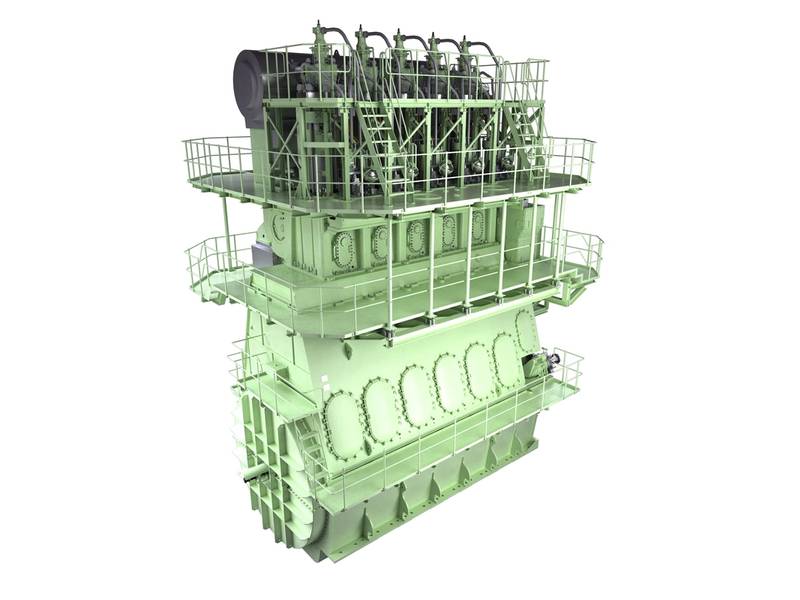

The G-Type

MAN Diesel & Turbo’s G-type program entered the market in October 2010 with the entry of the G80ME-C9 model. The G-types have designs that follow the principles of the large-bore, Mark 9 engine series that MAN Diesel & Turbo introduced in 2006. Their longer stroke reduces engine speed, there by paving the way for ship designs with unprecedented high-efficiency.

Such vessels may be more compatible with propellers with larger diameters than current designs, and facilitate higher efficiencies following adaptation of the aft-hull design to accommodate a larger propeller. It is estimated that such new designs offer potential fuel-consumption savings of some 4-7%, and a similar reduction in CO2 emissions. In this respect, the fuel savings and performance characteristics for propellers featuring MAN Diesel & Turbo’s unique Kappel blade design have been well documented in recent years. Simultaneously, the engine itself can achieve a high thermal efficiency using the latest engine process parameters and design features.

Since its introduction, close to 900 engines bearing the G-prefix have been ordered (including, now, 15 × G95 units), representing a total power output of some 15.9 GW. Of these, over 100 G-type engines have already entered service.

(As published in the November 2014 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

Related News