Demand for Maritime Shaft Generators Increasing

30 years ago shaft generators with PTI capability kept container ships sailing at top speed. That purpose gone, PTI/PTO is making a new comeback in more cargo shipping segments, this time for reducing emissions.

Retrofitting a shaft generator is not an insignificant undertaking. Around 50 tons of equipment needs to be installed into the engineroom through a hole in the hull. A new section of shaft is usually required.

That a few shipowners are undertaking such projects - Klaveness Combination Carriers on the Ballard, along with air lubrication, and Berge Bulk on the Berge Olympus, along with wind-assist – is testament to technology developments and the times.

A power take off (PTO) shaft generator can reduce genset operation time and therefore reduce fuel consumption by making better use of a ship’s less expensive main engine power. Adding power take in (PTI) functionality means the system can also act as a motor to provide the power boost needed to keep schedules in heavy seas or to navigate ice-infested waters without the need for overloading or oversizing the main engine. This power comes from gensets or batteries. With the addition of a clutch, PTI also enables a ship to run on full electric mode during port maneuvering and can provide safe return to port power in an emergency (power take home (PTH) mode).

Shaft generators are beneficial to EEDI/EEXI/CII calculations and can reduce fuel consumption by up to 20% thanks to the efficiency of modern permanent magnet technology that lowers their energy consumption and to the variable speed drives that enable them to provide constant power over a wider engine speed range.

Source: Berg Bulk

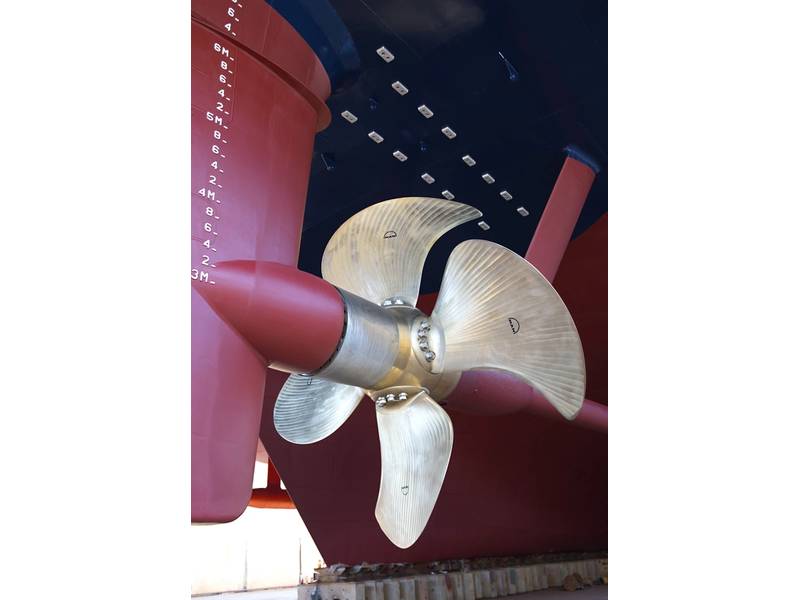

This added potential is mostly evidenced in the newbuild market where equipment suppliers are reporting increased interest from the cargo ship market. The specific fuel savings achieved will vary depending on whether the ship has a 2-stroke main engine or a 4-stroke-based electric power system, and whether it has controllable or fixed pitch propellers. The propulsion configuration is important, because specification of shaft generators involves careful optimization of engine and propeller. Propeller efficiency and cavitation are considered along with the efficiency of the engine over a range of power outputs.

Source: MAN Energy Solutions

“We do a lot of optimization,” explains Jens Ring Nielsen, Senior Technology Engineer at MAN Energy Solutions. “If you ask an engine designer about the most efficient way of operating, they’ll point to one path on the engine map. If you ask the propeller OEM, they’ll say another. The truth is somewhere in between.”

Specific considerations, such as whether to have a clutch between the shaft generator and the main engine or whether to have a primary or secondary shaft installation, depend on how the system is intended to operate, says Oskar Levander, VP Strategy & Business Development, Kongsberg Maritime. For example, a primary shaft-driven PTO rotates whenever the engine is running; a secondary one whenever the propeller is rotating. “A secondary PTO/PTI is used if you want to run the propeller with only the electric motor (PTI) without using the diesel engine. If you only intend to use a PTO and want to use it in port without the propeller, then you select a primary PTO.”

Source: The Switch

The Switch’s shaft generators start from <1MW and range up to 12MW+, although the biggest existing projects are around 5MW for large container ships. In a typical LNG carrier or other bulk carriers, permanent magnet technology improves efficiency by 2-4% compared to the synchronous machines that were commonly used in the past, says Dr Jussi Puranen, Head of Product Line, Electric Machines, at Yaskawa Environmental Energy / The Switch. This adds up to several million dollars in fuel savings over the lifetime of the vessel.

The Switch has over 100 shaft generators in operation and well over 100 in its production pipeline. Most commonly to date, orders have been for 174,000cbm LNG carriers. These vessels typically have two propulsion lines, with about 2MW PTO power from each. Now, 15-20,000 TEU container ships are adding to the company’s order book. These typically have one propulsion line with the shaft generator providing about 5MW of electric power.

Payback time for ABB’s PTI/PTO system is five years at current fuel prices (far less for new fuels). Michael D. Christensen, VP Global Sales, Dry Cargo Vessels at ABB, is seeing greater take up on bulker newbuilds, but not yet across all vessel sizes. “CII is a complex equation, and while the addition of PTI/PTO can bring a commercial advantage, it’s too soon for this impact to flow through to smaller bulkers. These vessels continue to come standard from shipyards, so while everyone wants sustainability, there are still other commercial considerations for shipowners.”

PTO can sometimes reduce CAPEX elsewhere in the propulsion train. “There’s the option to use a fixed pitch bow thruster which is significantly cheaper than a controllable pitch one once you have a variable speed shaft generator specified,” says Christensen. An active front end converter with a DC Link means you can add the control of the thruster, he says.

Additionally, shipowners can move further towards the IMO’s 2050. They can test out energy storage and fuel cell equipment, he says, and see what benefits they provide in practice compared to a diesel genset.

Shipowner Aasen Shipping provides a demonstration of how to turn the 20% savings from a shaft generator into 50% as part of a hybrid propulsion system. By combining a Wärtsilä 26 main engine with batteries, PTI/PTO and an intelligent energy management system, along with electrically powered machinery and an optimized hull and cargo design, the company’s two newbuild self-discharging bulk carriers were projected to cut fuel consumption by 50% compared to standard self-discharging vessels of a similar size. In December 2023, after two years of operation, the company demonstrated its satisfaction with the vessels by choosing a similar system for three new ones.

While the PTI was only part of a larger solution package, Torsten Büssow, Director for Ship Electrification at Wärtsilä, notes its importance: “Generally, with the increasing complexity of propulsion trains, the share of PTI in shaft generator applications has been growing from roughly below 10% to 25%, so it is definitely growing in demand.”

Source Wärtsilä