COATINGS: Chasing Better Prospects

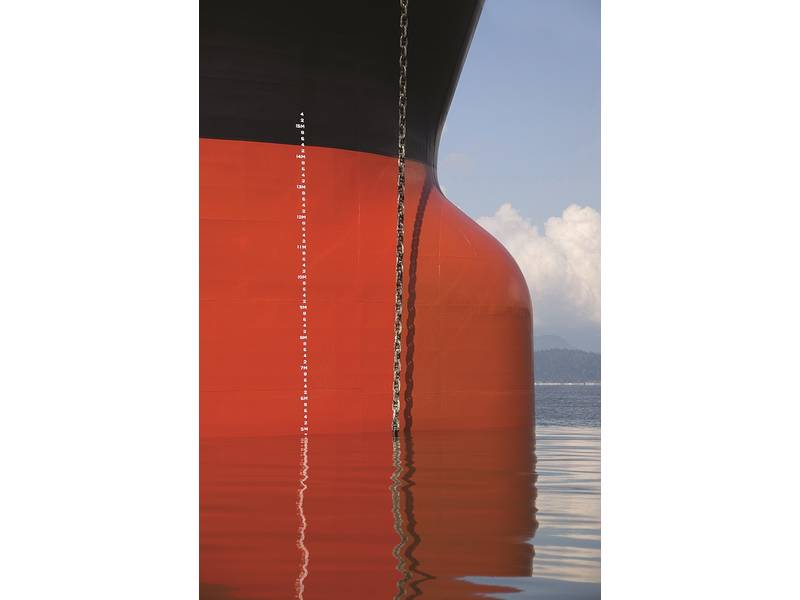

As the offshore industry recovers, choosing the right hull coating for those newly activated assets will be equally important.

The global offshore support vessel (OSV) market is still recovering from a protracted slump, but thankfully momentum is now returning with predictions for significant activity for OSV’s ahead. As summarized in a report by market analysts Grand View Research, projections are for the OSV market to exceed USD 71 billion by 2022 on the back of a significant increase in projects reaching final investment decision (FID) status, and a rising demand for oil and gas worldwide. This translates into a compound annual growth rate of more than 11 percent from 2015 and represents significant opportunities for owners and operators of these workhorses of the offshore energy industry.

Yet, it would be remiss to suggest the picture is entirely positive. A significant proportion of existing offshore support vessels are still laid up, sitting out of action waiting to secure favorable rates. According to figures from market data platform VesselValue, 36 per cent of OSV’s were laid up at the start of this year, with similar percentages out of action in the US Gulf, Middle East, West Africa and North West Europe. This represents a sizeable portion of the global OSV fleet sitting idle or in dry dock. Many of these vessels have been out of service for quite some time, and – with better prospects on the horizon – owners ought to be preparing these ships to come back into service.

Getting Back to Work

Ensuring the right hull coatings are applied in good time is a critical step, and careful consideration is given to investing in protective coatings solutions that will enable these vessels to operate efficiently for the longest possible amount of time. It is widely known across the maritime industry that fuel consumption is greatly influenced by the quality of the antifouling system used. The smallest micro-fouling is caused by slime and can result in an increased fuel consumption of between 1-2 percent, as the vessel uses more fuel to counter drag caused by biofouling.

Macro-fouling – seaweed, barnacles, oysters and mussels – could increase fuel consumption by as much as 40 percent, by increasing resistance against the hull as the vessel moves through the water. This means, at its most basic component, that more power is required to move the vessel at the desired speed. Most hull coatings today are designed to reduce this hydrodynamic drag by making the hull as smooth as possible and by preventing the build-up of marine organisms. It seems obvious to say, but it is a point often ignored: it is more cost efficient to apply an effective hull coating from the outset and avoid the extra fuel to counter the drag caused by fouling.

Knowing What You Want

As a leading worldwide manufacturer of coatings, Hempel understands the unique operational and environmental pressures that OSV’s must withstand and have worked for many decades to develop new technologies and finesse our solutions to deliver maximum returns. Our coatings are selected and applied based on a rigorous assessment of vessel particulars, anticipated trading patterns and service life, amongst other factors. Working closely with owners, yards and applicators – to ensure that the most appropriate solutions are applied and done so in a timely fashion – is a critical part of that interaction.

For all offshore support vessels, choosing a hull coating which reduces drag, minimizes downtime, enhances physical durability and protects assets for the longest period of time is a simple way to increase efficiency gains. For example, Hempaguard X7, Hempel’s most advanced hull coating to date, is one of the best coating systems available for OSV’s of all classes and specifications.

Hempaguard is the first coating to be built on the firm’s Actiguard technology, which is the only paint to combine both silicone-hydrogel and advanced biocide control in a single coating. Unlike regular hull coatings, which are usually selected to meet the vessel’s speed and activity level,

Hempaguard coatings retain effectiveness when switching between slow and fast steaming and low/high activity – so a vessel can change sailing routes and trading patterns without losing performance.

This is absolutely critical for the offshore support operations, by providing shipowners and operators with enhanced flexibility in their fleet utilization. What’s more, these coatings remain effective in waters of varying temperatures and during idle periods of up to 120 days – again, critical to offshore support operations – which regularly sit in stasis for extended periods before springing into action.

Always think longer-term

Naturally, owners and operators should be working with their coatings partner to find the most cost-effective coatings solution for their vessel and their business needs. This by no means should be about rushing to find the cheapest or most readily available products on the market. Rather, owners and operators should be more selective, and find a solution that will enhance operational efficiency and protect assets longer term.

This is why coatings based upon Actiguard technology are a prudent choice. It is important to remember that coatings are not purely aesthetic; they enhance a vessels ability to operate efficiently. Vessels coated with the right protection will stay in better shape for longer and will continue to attract the right attention as offshore players begin looking for partners. So, while these vessels may have been out of the game for a little while, there is no reason why – with the right armor in place – their operators should settle for anything less than the best the market can offer.

Davide Ippolito is the Head of Marine Group Product Management, Hempel A/S

This article first appeared in the September print edition of MarineNews magazine.