AMETEK Land Launches New Emissions Monitoring Systems

AMETEK Land, a provider of combustion efficiency and environmental pollutant emissions monitoring instrumentation, has launched two new continuous emission monitoring systems (PM-CEMS) to provide accurate and reliable measurement of particulate matter from industrial combustion processes in stacks and ducts.

The AMETEK Land 4650-PM is an extremely stable and accurate low-range particulate matter measurement system designed for CEMS applications where condensed water is not present in the flue gas. Consisting of a stack-mounted probe and separate control unit, 4650-PM’s forward scattering laser measurement detects particulate matter at low concentrations. This enables closer emissions control, with a more accurate measurement than similar PM monitoring systems.

Maximum measurement stability is achieved by the 4650-PM thanks to an advanced optical system with a lower angle of incidence than competing systems, resulting in a lower detection limit, while the optics are fixed for measurement reliability. The 4650-PM meets US-EPA Performance Specification 11 (PS-11) and is ideally suited for users who need to comply with US EPA rules, including MATS and Boiler MACT.

Out of the two new models, the 4650-PM has a superior calibration check mechanism and is less susceptible to changes in particle size, which is required where accuracy is key. It provides a highly sensitive measurement and is capable of measuring concentrations from 0.01 to 200 mg/m3. Offering the highest stability and reliability, 4650-PM can be used in stack temperatures up to 500 °C / 930 °F.

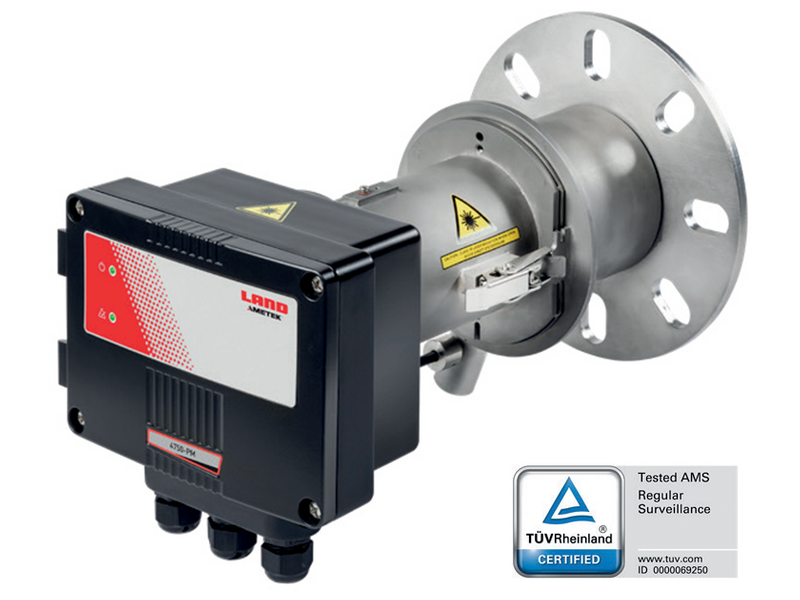

The additional new monitor, the AMETEK Land 4750-PM, also provides accurate and reliable measurement of particulate matter where condensed water is not present but uses a high-sensitivity back scattering technique. With a rugged design suitable for a wide range of applications, it features a highly stable optical system, with large-area collection, offering a low detection limit of less than 1 mg/m3.

TUVdotCOM approved to EN 15267, the 4750-PM measures concentrations from <1 to 10,000 mg/m3. It is not affected by flue gas conditions and operates to standard temperatures up to 250 °C / 400 °F.

Suitable for less-demanding applications, the 4750-PM comprises a stack-mounted sensor with combined internal user interface. All inputs and outputs are connected to the sensor for simple installation and ease of use. Digital and analogue outputs are sent back to the data acquisition system directly, as required. Remote triggering of calibration and purge fail sensor are additional options, as is a flue gas protector. The 4750-PM monitor has no moving parts; therefore, it will give years of trouble-free operation. A simple manual calibration check allows the instrument’s zero stability to be verified while the process is operating.

Both models provide a cost-effective and reliable continuous emission monitoring system to plant operators in electricity generating units, industrial boilers, glass works, cement plants, metal refineries and process heaters who are required to monitor their particulate emissions for regulatory compliance or for control purposes.