3D Scanning Speeds Up Drag Boat Racing

NVision, Inc., a company in 3D laser scanning and reverse engineering for over 24 years, said it was able to help a motorsports boat designer optimize the design of the custom-built propellers created for its Top Fuel Hydro drag boat.

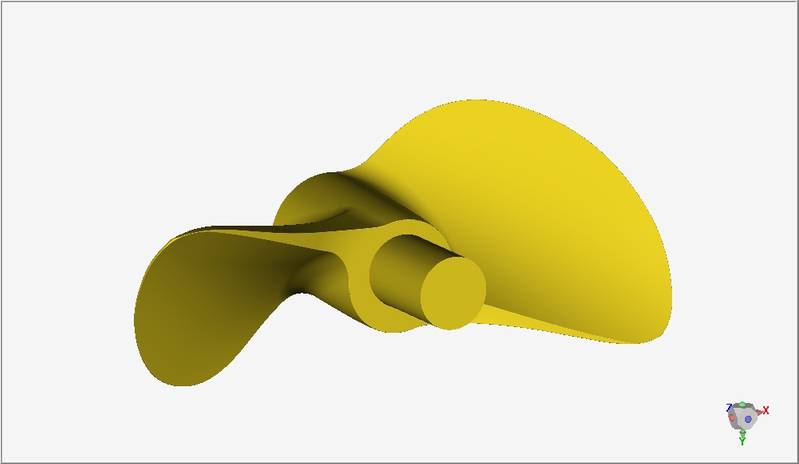

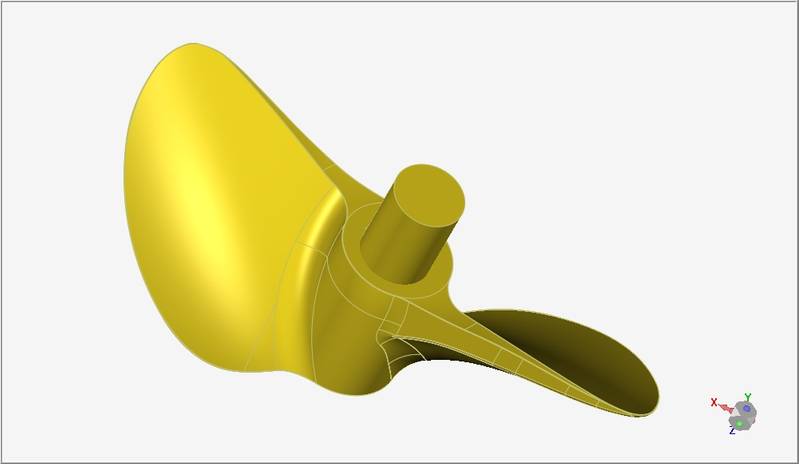

The boat is equipped with two custom-designed and handmade propellers. The double-bladed propellers worked well but the boat maker felt their design could be improved further to produce even greater speed and power. In order to achieve this goal, however, three things were necessary: one, the boat maker needed to document the propellers’ exact geometry; two, the geometry then needed to be analyzed for areas of possible improvement; and three, the final propellers needed to be identical to one another.

The boat maker sent the propellers to NVision, where engineers 3D mapped them with the company’s HandHeld scanner to capture all their geometrical information within a tolerance of +/- .001”.

The NVision Handheld scanner is a powerful portable scanning device that is capable of capturing 3D geometry from objects of almost any size or shape. The scanner is attached to a mechanical arm that moves about the object, freeing the user to capture data rapidly with a high degree of resolution and accuracy. As a part is inspected, the scanner generates a point cloud consisting of millions points each with x,y,z coordinates and i,j,k vectors. Integrated software that comes with the scanner is used to convert the point cloud to an STL polygon and an optional tripod provides complete portability in the field. Intuitive software allows real-time rendering, full model editing, polygon reduction and data output to all standard 3D packages.

“After the 3D laser scanning of the propellers, we were able to provide the boat maker with computer-aided design (CAD) files that showed each propeller’s exact geometry as well as where the two geometries deviated from each other. Using the reverse engineered CAD model, the boat owner, working with NVision’s engineers, was able to make the necessary design modifications to improve the propeller performance as well as to make both props identical,” Kersen said.

After installing the two redesigned, and now identical, propellers on the boat, the maker took the boat out and proceeded to break his personal best speed record. Kersen said, “This was a powerful demonstration of what can be accomplished by reverse-engineering with highly accurate 3D laser scanning technology.”

NVision’s expertise in reverse-engineering for the marine industry also includes the company’s recent work in helping a premier wakesurfing boat manufacturer document the geometry of one of its new handcrafted hulls. “For production, the manufacturer needed a CAD file with the exact geometry of one of its new handmade hulls. Our engineers visited the manufacturer’s site and, using our HandHeld laser scanner, conducted a complete scan of the hull and provided a precise CAD model of it to the manufacturer so production could begin,” Kersen said.

nvision3d.com