DNV GL's Sesam GeniE Reduces Engineering Costs

When warping analysis is required during design of certain types of beam offshore structures, it can involve many costly hours of manual calculations by senior engineers. With the new release of Sesam GeniE software, the most common methods of performing such analyses can be done automatically, saving time and resources.

Automatic warping analysis

“With the new release of Sesam GeniE, we have included automatic calculation of warping using the three most commonly used methods,” says Ole Jan Nekstad, Product Director for Sesam, DNV GL - Software. The software will free up engineering resources, as senior engineers will be freed up from the rote task of performing manual warping analysis. The number of total engineering hours will be reduced, as the calculation of one beam with an open section can often take many hours to calculate manually.

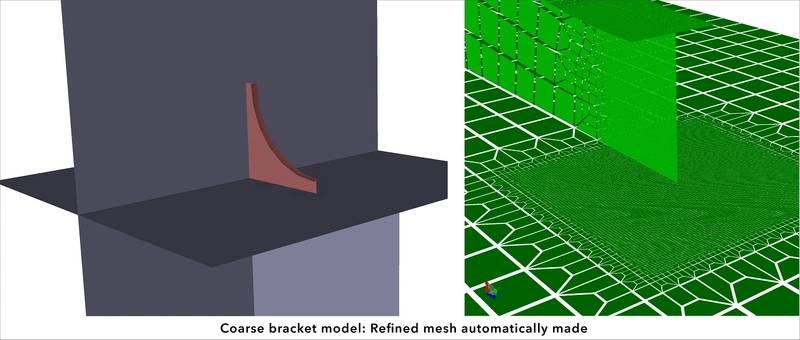

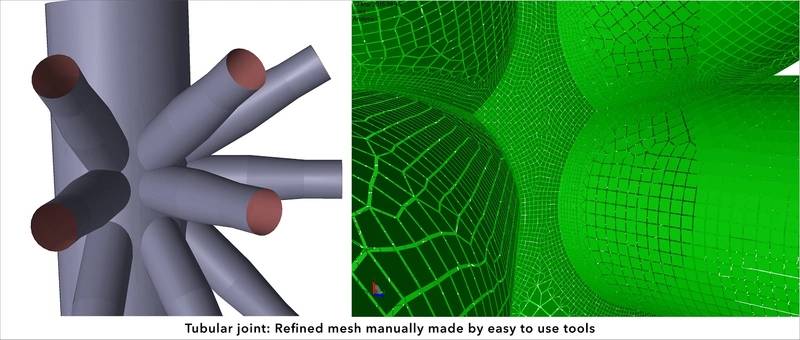

These new capabilities, significantly increasing the efficiency of beam design, come alongside meshing technology enhancements that strengthen Sesam’s leading position for topside local design. With the new Sesam GeniE, jacket design reanalysis including code check and report update can take up to 50 percent less time for engineers to complete. The code check modelling technique is flexible, combining multiple methods.

Leaders in offshore engineering

“With this release we confirm our position as a leading provider of the industry’s most efficient engineering solution,” says DNV GL - Software CEO, Are Føllesdal Tjønn. “In times where everyone is chasing cost reduction we enable this by continuously working closely with users, creating efficient solutions and implementing best practices for engineering tasks. Sesam is used across asset types such as ships, MOUs, jackets, subsea and topsides, allowing engineering activities to be organized in the most cost-efficient way,” he says.

“With Sesam, engineers have flexibility,” says Nekstad. “The new warping analysis capabilities can save the cost of having a senior engineer do manual calculations, which can mean days of work, depending on the project. Manual calculations are complex and also more subject to error. With automatic warping analysis, the results will be the same every time.” he says.

The American Institute of Steel construction (AISC) Torsion guide book includes nine rules for calculating warping torsion, where extra loads are added. Sesam GeniE now supports rules 3, 4 and 7, which are the most commonly used rules. In addition the new Sesam GeniE, version 7.3, has significantly improved calculations for marine growth, making fatigue analysis and load calculation more accurate.